- Meta Materials Circular Markets

- MMCM

- ELVs

- Tata Re.Wi.Re

- Mahindra CERO

- Nitin Chitkara

- Yashodhan Ramteke

MMCM Launches India’s First End-of-Life Vehicle Carbon Credits

- By MT Bureau

- October 29, 2025

Meta Materials Circular Markets (MMCM), a circular economy solutions platform, has announced the launch of India’s first circularity-linked carbon credits from End-of-Life Vehicles (ELVs). The company expects the project to achieve 2 million tonnes of CO2 savings by the end of the decade.

Under the Cercarbono standard, MMCM said it has introduced a global solution by integrating circular economy principles into carbon markets. This establishes a verifiable mechanism that links carbon reduction with material recovery.

The credits are expected to see demand, positioning India as a supplier of high-integrity, circularity-linked carbon assets. The project has the potential to unlock INR 10 billion in climate finance for the Registered Vehicle Scrapping Facilities (RVSFs) ecosystem.

MMCM has partnered with over 20 RVSFs nationwide, including Tata Re.Wi.Re and Mahindra CERO.

For every one tonne of ELV responsibly scrapped and recycled, approximately 0.6 tonnes of CO2 emissions are saved. These credits not only capture avoided emissions but also the recovery of materials such as steel, aluminium and plastics, which are reintroduced into manufacturing cycles. This creates a dual advantage for India Inc – credible Scope 3 emissions offsets and the development of low-carbon supply chains.

Nitin Chitkara, CEO, MMCM, said, “Circularity-linked carbon credits open a new paradigm where India can decarbonise while simultaneously creating value from recycling. This model not only supports India’s net zero ambitions but also strengthens industrial ecosystems with sustainable resource recovery. As COP30 nears, India is ready to showcase carbon innovation with global impact.”

Yashodhan Ramteke, Head of Carbon BU, MMCM, added, “By quantifying and trading ELV-linked carbon credits, we are demonstrating how emission savings and circularity can work together, setting the stage for India to become a leader in next-generation carbon finance.”

The initiative aims to reimagine ESG (Environmental, Social and Governance) strategy by turning automotive waste into an economic opportunity, strengthening industrial supply chains and accelerating progress on the Net Zero pathway.

Mahindra Expands Aftersales Capabilities In Delhi-NCR

- By MT Bureau

- February 10, 2026

Mahindra & Mahindra (M&M) has expanded its aftersales service network in the Delhi-NCR region, which includes the establishment of a training centre, the deployment of mobile service units and the addition of new service touchpoints.

The company has established the Mahindra Institute of Learning Excellence Centre, a 26,000 sqft facility designed for staff training. The centre includes an experiential learning hall and provides instruction in sales, mechanical service and bodyshop operations. The facility aims to update the skills of professionals handling the company's portfolio of electric and internal combustion engine SUVs.

Mahindra is deploying dedicated eVans (Electric Vehicle Assistance Network) across Delhi-NCR, which are designed to provide maintenance for electric SUV owners at their doorstep.

The eVan capabilities include periodic maintenance and washing, minor repairs, battery pack with integrated charger, hydraulic scissor lift & wheel balancer and car care services.

The company intends to expand this mobile service to other cities in the coming months.

Mahindra is also adding five service touchpoints in the region, increasing its capacity by the equivalent of 70 working bays. This expansion includes a dedicated commercial vehicle facility in Northwest Delhi. The move is intended to reduce turnaround times and improve service accessibility for the SUV portfolio.

Autoverse Mobility And GetAFix Integrate To Connect Manufacturers And Mechanics

- By MT Bureau

- February 09, 2026

Autoverse Mobility has announced a strategic integration with GetAFix, a garage management platform developed by Evenforce Technologies. The partnership aims to link parts procurement with workshop operations into a single digital workflow.

The system connects participants across the automotive aftermarket value chain, including manufacturers, distributors, garages and mechanics.

The core of the integration allows parts procurement requests to originate within the GetAFix platform for fulfilment by Autoverse. When a service advisor creates a job card or estimate, the system enables part identification, pricing and availability checks.

Real-time updates are reflected within GetAFix, providing workshops with visibility over the fulfilment process. For multi-brand garages, this eliminates manual coordination between workshop management and parts sourcing.

The integration provides specific outcomes for different sectors of the industry:

- Garages and Mechanics: Access to parts with assured fitment and reduced turnaround times for vehicle repairs.

- Manufacturers and Suppliers: Direct demand signals from repair jobs allow for improved forecasting and availability planning.

- Distributors: Predictability is enhanced through digitised order flows.

- Customers: Access to transparent estimates and faster repair completion.

Mihir Mohan, Founder and CEO, Autoverse Mobility, said, “The automotive aftermarket has traditionally operated in silos, with manufacturers, distributors, garages, and mechanics working on disconnected systems. This integration with GetAFix is a step toward changing that reality by building a connected ecosystem where information, demand, and fulfilment flow seamlessly from the factory floor to the mechanic’s bay.”

Srinath Rao, Founder and CEO, GetAFix, added, “Our focus has always been on simplifying workshop operations. By integrating Autoverse’s procurement and fulfilment capabilities directly into GetAFix, we are extending that simplicity beyond the workshop to the entire aftermarket ecosystem.”

The collaboration is designed to create a data-driven aftermarket system that reduces inefficiencies between production and last-mile consumption.

boAt Enters Automotive Aftermarket With Hive Dashcam Series

- By MT Bureau

- February 08, 2026

boAt has expanded its product portfolio into the automotive segment with the launch of the Hive Dashcam series. The range consists of three models: the Hive Dashcam F1, M1 and E1, designed to provide visual evidence for road incidents.

The series utilises Sony STARVIS sensors to manage recording in low-light and high-glare conditions. The devices are intended to assist with accident disputes, insurance claims and legal clarity.

The lineup caters to different user requirements, from flagship hardware to entry-level units:

- boAt Hive Dashcam F1: A dual-channel system featuring 4K front and 1080p rear recording. It includes an Advanced Driver Assistance System (ADAS) with voice alerts for lane departures and collisions, alongside built-in GPS and voice control.

- boAt Hive Dashcam M1: Records in 2K QHD through a 140deg wide-angle lens. It features a G-sensor for collision detection, GPS for speed logging, and supports storage up to 512GB.

- boAt Hive Dashcam E1: An HD unit recording at 1296p. It is designed for urban commuting and taxis, featuring loop recording and smartphone app connectivity via Wi-Fi.

The Hive series includes intelligent parking surveillance triggered by motion detection and G-sensors to monitor unattended vehicles. Data is managed via onboard microSD storage, with options for smartphone integration and cloud connectivity.

Gaurav Nayyar, CEO, boAt, said, “As we continue to expand boAt’s portfolio beyond audio and wearables, our entry into dashcams is a natural extension of our vision to build smart, meaningful tech for today’s consumers. With Indian roads becoming increasingly complex, dashcams are no longer a luxury but a necessity. At boAt, we aim to bring reliable, well-engineered and design-forward solutions that make everyday journeys safer and more confident.”

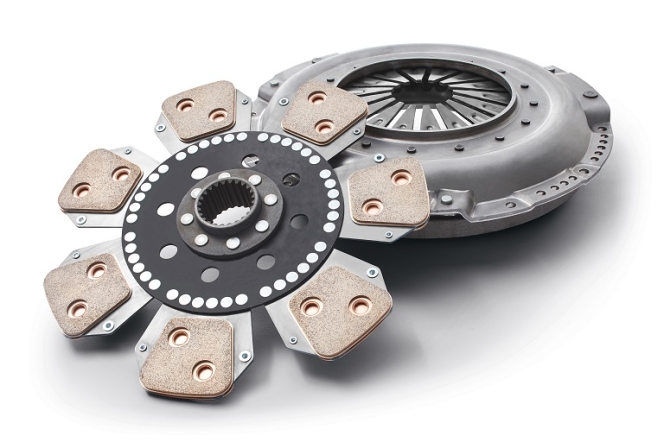

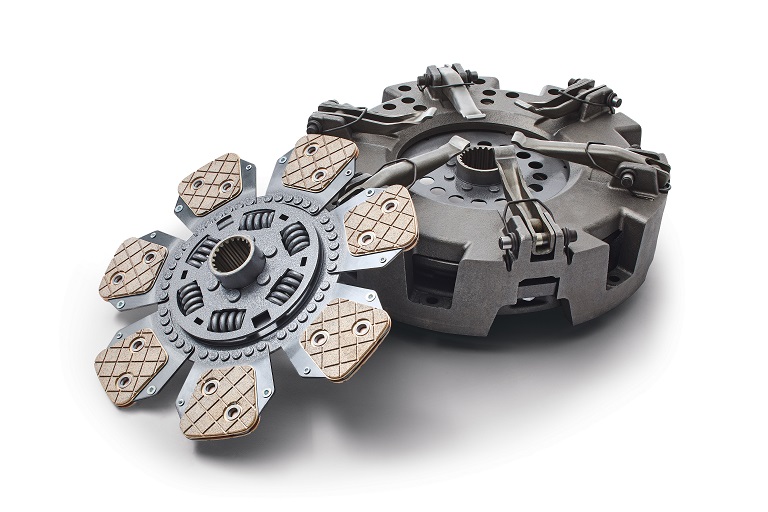

ZF Aftermarket Launches SACHS Clutch Solutions For Agriculture

- By MT Bureau

- February 07, 2026

ZF Aftermarket has introduced a new line of SACHS Clutch Discs and Kits specifically engineered for agricultural tractors, merging global engineering prowess with local production in India. This strategic launch enhances product availability across India and the broader IMEA region, including the Middle East, Africa, Türkiye and CIS markets. The products will be publicly unveiled at ACMA Automechanika 2026 in New Delhi, where ZF will demonstrate its latest technologies, reinforcing its role as a leading agricultural machinery component provider.

Crafted to endure the demanding cycles of modern farming, these clutch solutions prioritise exceptional durability, smooth operation and long-term reliability. Key engineering features ensure stable performance through high-quality friction linings and robust construction that resists harsh conditions. Components are designed for optimised heat dissipation and corrosion resistance, extending product life even under heavy loads and challenging terrain.

Operator comfort is significantly enhanced through designs that minimise noise and vibration, enabling a quiet drive and smooth engagement for precise control. This focus on acoustic and driving comfort supports farmers during long working hours. Additionally, the kits offer straightforward serviceability, with easy installation to reduce downtime and broad compatibility across numerous tractor models. They deliver original equipment quality and proven reliability, backed by the trusted SACHS brand and ZF’s industrial expertise.

By manufacturing these clutches locally, ZF addresses the growing regional demand for durable, low-maintenance agricultural components, providing farmers and OEMs with a performance advantage. This initiative supports equipment uptime and operational efficiency while aligning with ZF’s strategy to deliver advanced, sustainable solutions tailored to local needs. Ultimately, this launch underscores ZF Aftermarket’s commitment to redefining mobility in India and beyond through reliable, innovative aftermarket solutions.

Abhishek Verma, Head – ZF Aftermarket, India, said, “The introduction of our new SACHS agricultural clutch range marks an important step in strengthening ZF Aftermarket India’s growth trajectory. By combining German engineering excellence with local manufacturing capability, we are expanding our ability to deliver high‑quality, high‑reliability solutions tailored for regional needs. This launch reinforces our commitment to deepening market reach, enhancing product availability and supporting the long‑term growth of the agricultural ecosystem across India and the wider IMEA region.”

Andre Scholle, Head – ZF Aftermarket, IMEA (India, Middle East, Africa, CIS), said, “The introduction of SACHS agri clutch is a milestone in our strategy execution to maximise Mobility Uptime. It offers a dependable, high comfort solution that sustains productivity season after season. Built with precision manufactured components and durable materials, SACHS agri clutches provide OE level quality that ensures consistent operation even in harsh working environments.”

Comments (0)

ADD COMMENT