Sterling Tools Partners UK’s Advanced Electric Machines To Make Rare Earth Magnet Free Motors In India

- By MT Bureau

- May 14, 2025

Delhi NCR-based automotive component manufacturer Sterling Tools, through its subsidiary Sterling Gtake, has inked a technology licensing agreement with Advanced Electric Machines (AEM), UK to enter the electric vehicle motor market.

As per the understanding, Sterling Gtake will develop, manufacture and market Rare Earth Magnet-Free traction motors for EVs in India.

The component supplier stated that by introducing a mature and commercially viable rare earth magnet-free technology, it will be able to offer its customers an alternative to the China dependent permanent magnet supply chain.

It expects that the traction motors market will to grow to around INR 150 billion by 2030. Furthermore, Sterling Gtake will also explore joint development of integrated motor and controller solutions.

Anil Aggarwal, Chairman, Sterling Tools, said, “Sterling’s foray into rare earth magnet-free motors demonstrates the Group’s commitment to being a technology leader and an industry pioneer. We are expanding beyond MCUs to being a complete solution provider and meeting the EV Industry’s growing demand for advanced technology. EV sub-systems are being increasingly consolidated into multifunction units and Sterling will also offer our customers integrated motor and controller solutions. The Sterling Group will continue to extend excellent technical and application support to its customers to help drive greater adoption of EVs in India.

“The diversification into rare earth magnet-free motors is in line with Sterling’s ambition to develop powertrain expertise to serve the Indian auto industry. Sterling Tools plans to further expand the local manufacturing of EV Solutions, strengthening India’s industrial supply chain. With the EV market poised for significant growth, this partnership is well-timed to capitalise on emerging opportunities while contributing to a sustainable future.”

Dr. James Widmer, Co-Founder & Chief Executive Officer, Advanced Electric Machines, said, “India’s automotive and zero-emission manufacturing market offers immense potential for growth and innovation. Through our partnership with Sterling Tools, we are bringing our proven expertise in magnet-free motors to Indian customers across a wide range of vehicle categories. Together, we can create high-quality powertrain solutions that cater to India’s growing need to reduce its tailpipe emissions, while also supporting the country’s self-reliance and sustainability goals.

This agreement is a culmination of a strong relationship between the two companies, and we have worked with SGEM over several years to understand the Indian market and develop the local supply chain. We are now ready to hit the ground running and to contribute to India’s quest for sustainability.”

ZF India Secures Contract To Supply Electric Low-Floor Axle For E-Buses

- By MT Bureau

- February 16, 2026

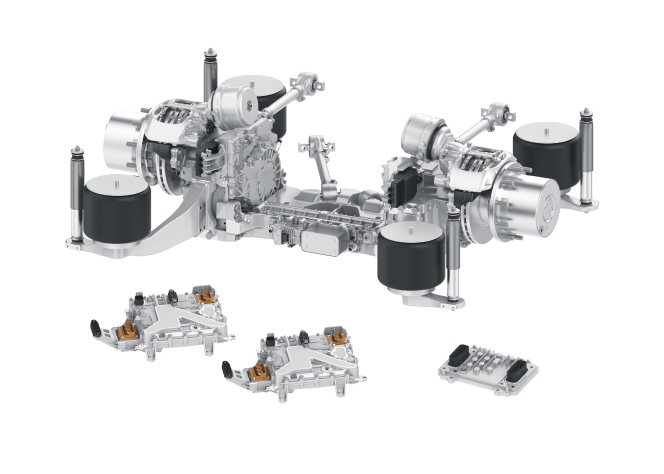

German automotive component supplier ZF India has secured a contract from an Indian original equipment manufacturer (OEM) to supply the AxTrax 2 LF electric portal axle. The technology will be utilised in 11-metre city buses and 18-metre articulated buses for domestic and export markets.

The nomination, confirmed in October 2025, involves a multi-year programme for several thousand units, with deliveries scheduled to begin in 2026.

The AxTrax 2 LF integrates propulsion, braking and suspension within a single unit. This architecture replaces the engine, transmission, and conventional axle, increasing space for passengers and batteries. The system uses the same mounting points as previous generations, allowing for backward compatibility.

The unit is built on a modular platform featuring:

- Dual PMS Motors: Two permanent magnet synchronous hairpin motors.

- Inverters: Two 800V Silicon Carbide (SiC) inverters.

- Power Output: Continuous power variants of 260 kW and 360 kW.

- Torque: Peak torque of 36,800 Nm.

An oil cooling system with an integrated e-pump manages temperature and lubrication to maintain performance. The system is compatible with battery-electric, hydrogen fuel cell and trolley bus configurations.

The axle includes software for torque vectoring, regenerative braking, hill hold, and axle condition monitoring. It is designed to meet ISO 26262 functional safety requirements and cybersecurity standards. The electronics are capable of receiving over-the-air (OTA) updates.

Akash Passey, President - ZF Region India, said, “AxTrax 2 LF enables OEMs to design buses that maximise passenger and battery space while delivering superior efficiency and reliability. Its compatibility with battery-electric; fuel cell and trolley bus platforms enable ZF to address the zero-emission mobility aspirations and reinforces the country’s emerging role in next-generation commercial vehicle technology.”

Paramjit Singh Chadha, Senior Vice-President - CVS, ZF Group (Region India), said, “By combining propulsion, braking, suspension, low noise, comfort, safety and intelligent electronics within a compact architecture, ZF helps OEMs simplify vehicle design and accelerate development timelines. Our focus remains on partnering with customers to enable reliable, efficient and future-ready solutions for zero-emission transportation in India.”

Juan Manuel Molla Appointed Managing Director Lighting At Forvia Hella

- By MT Bureau

- February 16, 2026

Tier 1 automotive supplier Forvia Hella has appointed Juan Manuel Molla as the new Managing Director Lighting and member of the Management Board, effective 1 March 2026.

He succeeds Bernard Schaferbarthold, who has held responsibility for the Business Group Lighting on an interim basis, and has stepped down from the Management Board on 15 February 2026.

Molla, joins the company with over three decades of experience in the automotive industry. He has held leadership roles at various manufacturers and suppliers, most recently serving as Chief Commercial Officer at Marelli.

In his new role at Forvia Hella, Molla will oversee the strategic development of the lighting business, focusing on market requirements and technological innovation.

Dr.-Ing. Wolfgang Ziebart, Chairman of the Shareholder Committee, said, “With Juan Manuel Molla, we are gaining a highly experienced leader who brings strategic foresight, many years of industry experience, and a deep understanding of the needs of our customers as well as of international markets to the company. We are therefore very pleased to welcome Juan Manuel Molla to Forvia Hella and are confident that he will successfully continue – and further accelerate – the strategic development of the Lighting business in a dynamic and challenging market environment.”

Juan Manuel Molla stated, “I am very grateful for the trust placed in me. The automotive industry is undergoing profound transformation – which will bring changes, but above all great opportunities for the future. Our goal is therefore to respond to new market requirements with agility and flexibility, to consistently strengthen our competitiveness, and to drive the development of lighting innovations that are technologically pioneering and yet affordable. The greatest asset of Forvia Hella’s Lighting business is the expertise of our colleagues worldwide. I look forward to working with them to tackle these tasks and to shape the future of the Business Group Lighting together.”

TSUYO Unveils Powertrain Technologies Eor Electric Three-Wheelers

- By MT Bureau

- February 14, 2026

Bengaluru-based TSUYO Manufacturing has launched its new portfolio of electric motor and powertrain technologies aimed at the light commercial vehicle market in India. The release focuses on modular design and local innovation to support electrification in the three-wheeler segment.

The company introduced its Gen 3.0 IPM motor and controller architecture, which it claims includes external Hall sensor placement and split-phase cabling to manage heat dissipation and reliability. The controller features an aluminium cast housing for thermal performance, an external bootloader for software updates and an LED system for diagnostics. The architecture also utilises upgraded MOSFET technology for high-performance applications.

TSUYO announced several technologies designed to improve vehicle efficiency and resource independence:

- Automated Manual Transmission (AMT): An AMT solution for electric three-wheelers intended to improve range, load handling, and gradeability.

- SynRM Motor: A patented magnet-less motor featuring a rotor architecture that reduces reliance on imported rare-earth materials.

- Hairpin Winding: This technology increases power density, claiming a 20% increase in performance and extended motor life.

- Axle Technology: A flat tube axle with a gear interface for L3 and Mini-L5 vehicles to improve load capacity.

Vijay Kumar, Co-Founder and CEO, Tsuyo Manufacturing, said, “India’s electric mobility journey, especially in the three-wheeler segment, demands solutions that are engineered for reality—not mere specifications on paper. At TSUYO, this launch represents a decisive step in moving India’s EV ecosystem from assembly-led adoption to engineering-led innovation. Every product we are unveiling today has been designed to address the unique operating conditions, cost sensitivities, and performance expectations of Indian vehicles and end users.”

Tenneco Clean Air India Reports INR 1.18 Billion In Profit For Q3 FY2026

- By MT Bureau

- February 14, 2026

Tenneco Clean Air India has announced its financial results for Q3 and 9-month period FY2026. The company reported a 14.7 percent increase in value-added revenue (VAR) and a 24.8 percent rise in EBITDA compared to the same period last year.

Revenue from operations for the quarter stood at INR 12.85 billion, up 14.2 percent YoY, while profit after tax saw a decline of 5.3 percent YoY to INR 1.18 billion on the back of cost associated with new labour code implementation.

The company stated that it uses value-added revenue as its primary metric, which reached INR 11.94 billion.

Tenneco also announced that it has secured a contract to supply its DaVinci DCx suspension system to an Indian OEM (Mahindra) for an SUV platform. The program is estimated to generate INR 2.2 billion in annual revenue. The DaVinci technology utilises a mechanical design with discs to control hydraulic flow, avoiding the use of sensors or motors to manage ride quality.

Additionally, the company won a contract with a global commercial vehicle manufacturer for a modular BSVI aftertreatment system. This project has an annual revenue potential of approximately INR 1.15 billion.

Furthermore, the Board has approved the establishment of a greenfield Clean Air plant in Kharkhoda, Haryana. The project will see an estimated investment of INR 710 million, with production scheduled to begin in Q3 of FY2027. The facility is intended to support the light vehicle, off-highway and tractor segments.

Arvind Chandra, Whole-Time Director and CEO, Tenneco India, said, "The quarter demonstrated sustained execution across our business. We delivered strong business growth, resilient margins, and meaningful progress across Clean Air, Powertrain, and Advanced Ride Technologies. The selection of DaVinci DCx Suspension for a flagship SUV platform validates our product development approach and positions us to capture additional opportunities as OEMs seek to differentiate through ride quality. Unlike conventional systems, the DaVinci technology uses specially designed discs (or shim stacks) to control hydraulic flow, delivering consistent comfort across varying speeds and road conditions, achieved affordably and with a fast time to market."

Chandra also noted that the company's export order book covers 100 percent of projected FY2028 revenue, supported by tariff reductions in the US and EU.

Comments (0)

ADD COMMENT