As the world relies more on technology and data to tackle different situations or to streamline processes, loopholes exist inevitably. Orbitsys leverages its cloud-based platform, allowing centralisation of data along with remote access for the automotive industry to tackle dealerships and hurdles.

“We tackle connectivity and data hurdles in the automotive industry by offering a cloud-based platform. This allows dealerships and OEMs to centralise data, which eliminates scattered systems, creating a single source of trusted data for customer and vehicle information. Moreover, accessing data remotely enables secure, role-based and real-time data visibility across multiple locations, improving decision-making,” informed Harvinder Pal Singh, Chief Business Officer, Orbitsys DMS.

DEP Outlines Top 3 Future Priorities: R&D, Talent Acquisition And Market Expansion

- By Nilesh Wadhwa

- May 06, 2025

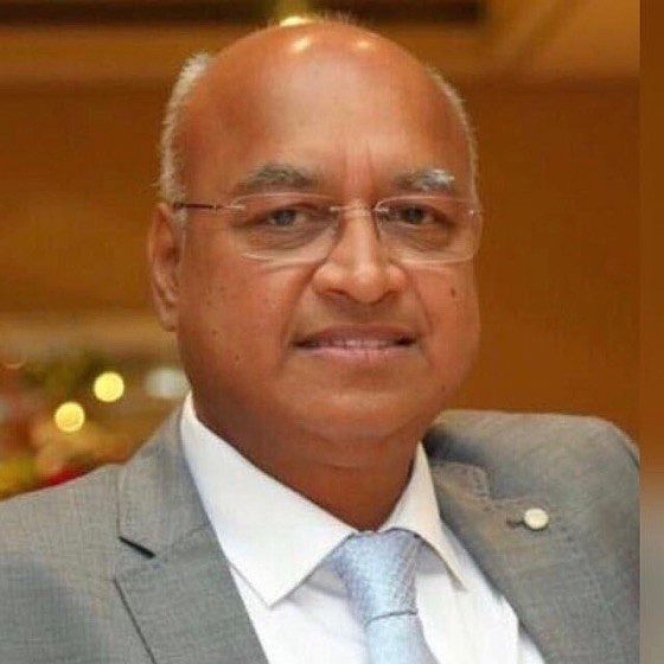

Radha Krishnan, President and Founder of Detroit Engineered Products (DEP), a Michigan-based leading engineering solutions and product development company, shares his perspective on the key trends in the automotive industry, challenges & opportunities, alternative energy and future growth plan.

How do you see the role of Artificial Intelligence (AI) and Machine Learning (ML) evolving over the years?

The role of AI and ML in engineering is set to evolve significantly in the coming years. At DEP we are already seeing how these technologies transform engineering simulation and product development. AI and ML are refining traditional numerical methods like Finite Element Analysis (FEA) and enhancing the speed and accuracy of solving complex 3D physics problems. These advancements not only improve solver efficiency but also introduce dynamic visualisation capabilities, enhancing the overall user experience.

Our proprietary platform, DEP MeshWorks, leverages a variety of AI algorithms that adapt based on customer data, ensuring relevance and accuracy. Moreover, the recent integration of generative AI capabilities allows engineers to create customised designs, streamlining the design process and enabling faster iterations. By facilitating predictive modeling and automating early-stage design tasks, AI and ML empower engineering teams to make more informed decisions quickly.

The evolving role of AI and ML is about enhancing creativity and efficiency in engineering, and we at DEP are excited to help clients harness their full potential for innovation and success across various industries using the technology.

With automakers increasingly relying on simulation and design tools to improve time-to-market, how is DEP helping the industry?

At Detroit Engineered Products, we understand the pressure on automakers to enhance their time-to-market. That's where MeshWorks 2025 comes in. We have developed it with cutting-edge AI and machine learning technology, which really transforms how engineering team’s work. Imagine cutting down your model building time drastically while achieving unmatched geometric accuracy. With MeshWorks 2025, you can say goodbye to tedious pre-processing. Our smart pre-processing and advanced meshing capabilities streamline your workflow, allowing you to automate repetitive tasks. This means you can focus on what truly matters – making the best engineering decisions. From concept to reality, we help optimise designs, improve performance and reduce costs and weight. MeshWorks 2025 isn't just a tool; it is a partner in innovation. It helps you achieve significant time savings and maximise companies RoI (Return on Investment) on every project.

What according to you are the key challenges faced by the automotive industry currently?

I see several key challenges that we are facing today. First and foremost, the transition to electric vehicles (EVs) is both a huge opportunity and a challenge. Companies must adapt their supply chains, rethink manufacturing processes, and invest in new technologies – all while managing costs. Another significant challenge is the growing demand for advanced driver-assistance systems (ADAS) and autonomous driving features. Integrating these technologies requires not only innovation but also strict regulatory compliance and safety standards. Additionally, we are navigating global supply chain disruptions that have been exacerbated by recent events.

Securing critical components, especially semiconductors, remains a top concern. Lastly, the push for sustainability is changing how we think about materials and production methods. Consumers are increasingly demanding eco-friendly options, and we must respond to this shift while maintaining performance and affordability. Overall, these challenges require us to be agile, innovative and forward-thinking as we work to meet the evolving demands of the market. Collaboration across the industry will be essential to overcome these hurdles.

What role does India play in your global scope of things?

India plays a crucial role in our global strategy. It is not only a significant market for DEP MeshWorks but also a hub for our research and development (R&D) efforts. We invest heavily in our R&D centres in India, which drive innovation and customisation of our platform. Additionally, India is home to a growing number of clients in various industries, including automotive, which contributes substantially to our revenue and growth. We see India as a vital player in our global footprint, driving both technological advancements and market expansion.

Which areas do you think are still lagging behind in the adoption of simulation and engineering design?

While many sectors have embraced simulation and engineering design, areas such as small to mid-sized manufacturers, particularly in emerging markets, are still lagging behind. Many of these companies lack the resources or expertise to fully leverage advanced CAE tools like DEP MeshWorks. Additionally, industries such as construction and agriculture, which could greatly benefit from simulation technologies, often rely on traditional methods and are slow to adopt digital solutions. We believe that with increased awareness and training, these sectors can unlock significant value through simulation.

It was at the Auto Expo 2020 that DEP showcased an electric scooter prototype. What has been the progress in terms of demand for such solutions from your customers?

Since the Auto Expo 2020, we have seen a substantial increase in demand for electric mobility solutions. Customers are increasingly recognising the importance of sustainability and are eager to adopt electric powertrains in their product lines. Our electric scooter prototype has sparked interest among various automakers and startups looking to innovate in this space. We are actively working with several clients to develop tailored solutions that meet their specific requirements, reflecting a clear shift in market demand toward electric mobility.

Similarly, you were working on converting diesel engines to petrol engines. What has been the progress on the same?

The conversion of diesel engines to petrol engines has been a significant focus for us, and we are making good progress. We have helped companies develop several prototypes and are conducting extensive simulations to ensure efficiency and performance. This aligns with the industry's push toward cleaner technologies, and we are excited about the potential impact of our innovations.

Has the evolution of electric powertrains and alternative fuels made development complex for the automotive industry, or has it become simpler?

The evolution of electric powertrains and alternative fuels has introduced both complexity and opportunities for the automotive industry. While the transition to electric and alternative fuel technologies brings challenges – such as redesigning systems for efficiency, meeting regulatory requirements and addressing supply chain issues – it also simplifies certain aspects, particularly in terms of reducing the mechanical complexity found in traditional combustion engines. Companies that embrace simulation tools like DEP MeshWorks can navigate these complexities more effectively, optimising designs early in the process. Overall, while the development landscape is more complex, it also offers exciting possibilities for innovation and sustainability.

Can you outline DEP’s focus areas for the next 3-5 years, especially for India?

Over the next 3-5 years, we plan to significantly increase our investment in India, focusing on three key areas: R&D, talent acquisition and market expansion. We aim to enhance our R&D capabilities by establishing state-of-the-art facilities dedicated to innovation in simulation technologies. Additionally, we will invest in recruiting top talent to drive our initiatives forward. Our goal is to expand our client base in India while providing tailored solutions that meet the unique needs of the local market. This strategic investment will reinforce our commitment to being a leader in the CAE space and support the growing demand for advanced engineering tools.

With new body styles being explored by the automotive industry and even new segments emerging such as flying cars, autonomous pods, and micro cars, how do you support such segments?

At DEP, we are committed to supporting the automotive industry's exploration of new body styles and innovative segments. Our DEP MeshWorks platform is designed to be flexible and adaptable, enabling engineers to simulate and optimise designs for a wide range of applications, from flying cars to autonomous pods and microcars. We provide advanced simulation capabilities that allow our clients to test various scenarios and configurations efficiently. By integrating AI and ML, we empower engineers to make informed design decisions early in the development process, minimising risks and accelerating time-to-market. As these new segments evolve, we are excited to partner with our clients to push the boundaries of innovation and bring groundbreaking solutions to life.

- Orbitsys Technologies

- Harvinder Pal Singh

- Dealer Management System

- DMS

- customer relationship management

- CRM

- Daewoo

- Skoda

- Isuzu

- Keeway

- Benelli

- Omega Seiki

- Revolt Motors

- Lohia Auto

- Amo Mobility

- Montra

Driving Innovation In Dealer Experience

- By Bhushan Mhapralkar

- March 19, 2025

Harvinder Pal Singh, Chief Business Officer, Orbitsys Technologies, spoke to Bhushan Mhapralkar, Editor, Motoring Trends, regarding the products and solutions his company offers to the automotive industry to enhance operational efficiency and lower costs.

What is the cloud-based dealer management software Orbitsys offers?

Orbitsys provides a comprehensive, cloud-based Dealer Management System (DMS) designed to streamline operations for OEMs, EV companies, auto dealerships and multi-brand workshops. Our platform integrates key functions like lead management, sales and after-sales operations and customer relationship management (CRM) into a single, seamless system. This allows businesses to move away from scattered tools and spreadsheets, improving efficiency and decision-making. The cloud-based nature of our DMS ensures real-time data accuracy, security and accessibility, enabling dealerships to stay agile in a rapidly evolving market.

Additionally, our mobile applications for OEMs, dealerships and vehicle owners foster better communication, enhancing customer experience and operational effectiveness. As the industry shifts towards electrification and digital transformation, Orbitsys equips businesses with the tools they need to adapt, scale and stay ahead of the competition.

How does the software sit with the OEMs and dealers in terms of optimising operations to streamline sales processes and to deliver high-quality service?

Our DMS seamlessly connects OEMs and dealers, optimising operations, streamlining sales and enhancing service quality. For OEMs, it provides real-time data and analytics, ensuring better dealer performance tracking and smoother order processing. It integrates with ERP/SAP systems, standardises workflows and enhances dealer support, creating a more efficient and data-driven ecosystem.

For dealers, the system automates lead management, sales, invoicing and service operations, reducing turnaround times and improving customer experience. The built-in CRM centralises customer data, enabling personalised service and higher retention. With cloud-based accessibility, dealers can manage operations from anywhere, improving efficiency across multiple locations.

The result is faster sales cycles, stronger dealer-OEM collaboration and a superior customer experience. All these help to drive business growth and profitability.

What are the comprehensive tools that are offered along with the software?

Orbitsys offers a suite of tools that empower OEMs and dealers to run their operations smoothly. These include Lead Management System that captures, tracks and nurtures leads for higher conversions. Sales and Inventory Management that automates pricing, invoicing and stock control for real-time accuracy. Workshop and Service Management that schedules appointments, tracks repairs and manages spare parts. CRM and Customer Engagement that centralises customer data to enable personalised service and retention. Also, mobile apps that are designed for dealership users, OEMs and customers to ensure seamless connectivity.

Tools such as these work cohesively to enhance efficiency, drive sales and improve customer satisfaction. They make Orbitsys a complete digital solution provider for the automotive industry.

What are the opportunities Orbitsys is tapping in view of the transformation the auto industry is going through?

The auto industry is undergoing a massive transformation, driven by the rise of EV brands, used car dealerships and multi-brand workshops – each facing unique challenges in scaling, customer engagement and operational efficiency. Orbitsys is at the forefront of this shift, offering tailored DMS solutions that eliminate inefficiencies and streamline business operations.

For electric vehicle (EV) brands, our specialised DMS includes Battery Management, Charging Infrastructure Integration, Energy Management and Telematics. These are features that are absent in conventional systems. By centralising operations, reducing costs and improving efficiency, Orbitsys is helping EV businesses to scale up faster and to enhance customer experiences, driving adoption of new technology.

For used car dealerships, Orbitsys solution simplifies inventory management, sales tracking, customer interactions and after-sales service, creating a seamless and profitable ecosystem. Integrated data insights improve decision-making while our platform ensures dealers can efficiently manage their growing business.

For multi-brand workshops, the company offers a comprehensive CRM-DMS solution that handles customer relationships, parts inventory, workflow automation and service tracking. This allows workshops to optimise operations, enhance service quality and boost profitability while keeping everything organised in one central system.

By addressing the evolving needs of these sectors, Orbitsys is empowering businesses to stay ahead in a rapidly changing automotive market – driving growth, efficiency and superior customer experiences.

Isn’t the use of software and comprehensive tools changing with the change in model demand and the proliferation of features, model mix, technologies and alternative fuel technologies?

Absolutely. The rapid shift in model demand, emerging technologies and the rise of alternative fuel vehicles is transforming how OEMs and dealerships operate. Traditional dealership management approaches no longer suffice, as businesses must now navigate a complex mix of connected vehicles, electrification trends and evolving customer expectations.

Orbitsys is staying ahead of this transformation with a flexible, cloud-based DMS that adapts to changing market demands. Our software leverages real-time data analytics, AI-driven insights and automation to help businesses streamline operations, manage diverse model portfolios and enhance digital-first customer interactions.

For EV brands, we offer a specialised DMS designed to tackle industry-specific challenges. Our system optimises the entire customer journey, from lead generation to post-sale service, ensuring a seamless and efficient experience.

Key features of Orbitsys’ EV DMS include Battery Management monitors battery health, performance and lifecycle data to ensure optimal efficiency and longevity. The Charging Infrastructure Integration seamlessly connects with charging networks, providing real-time station availability and efficient energy management. The Energy Management helps to optimise energy consumption and cost-efficiency through advanced analytics. Telematics Integration helps to collect and analyse vehicle data to enhance performance, safety and customer satisfaction.

By continuously evolving our DMS technology, Orbitsys ensures that dealerships, workshops and OEMs stay competitive, drive innovation and navigate the future of mobility with confidence.

How does Orbitsys’ software and tools aid customer centricity, integrity, adaptability, diversity and inclusion and operational efficiency?

At Orbitsys, we have designed our software to help automotive businesses stay competitive by focusing on these core pillars. When it comes to customer centricity, our DMS ensures personalised experiences with AI-driven insights, automated follow-ups and real-time engagement, making interactions more seamless and efficient. Integrity is built into our system with secure, cloud-based data management, ensuring transparency, compliance and reliability in every transaction, fostering trust between OEMs, dealers and customers.

With adaptability a key to today’s fast-changing industry, our software scales effortlessly with market shifts, whether it’s the rise of EVs, digital-first sales models or new customer expectations. We also emphasise diversity and inclusion by supporting multi-brand dealerships, multiple sales channels and multilingual interfaces, making our platform accessible to businesses and customers across different markets. Also, operational efficiency is at the heart of everything we do. By automating workflows, providing AI-powered analytics and integrating seamlessly with various business functions, we help dealerships and OEMs streamline their operations, cut costs and maximise profitability. What Orbitsys is doing is to empower businesses to be agile, customer-focused and future-ready in an evolving automotive landscape.

What are the challenges?

The automotive industry is undergoing rapid transformation, and with that comes several challenges. One of the biggest is keeping up with evolving technologies – from EV advancements to AI-driven automation. Dealerships and OEMs need solutions that adapt quickly, and ensuring our software remains ahead of the curve is a continuous effort. Another challenge is integration across diverse business models. With the rise of EVs, used car dealerships and multi-brand workshops, each segment has unique operational needs. Our focus is on creating a flexible yet comprehensive DMS that caters to all these verticals without complexity. Scalability is also a key factor. As auto businesses grow, their digital infrastructure must expand seamlessly. We work to ensure our solutions can handle increasing data, transactions and integrations without disrupting business flow. Finally, data security and compliance are critical in an era where digital transactions and customer data are at the core of operations. We continuously enhance our security framework to protect sensitive information while ensuring regulatory compliance. Despite these challenges, we see them as opportunities to innovate, refine our offerings and provide real value to our partners in this fast-evolving industry.

What is competition like for all that the company offers?

DMS space is competitive, with both legacy players and new entrants vying for market share. However, what sets Orbitsys apart is our deep industry specialisation and adaptability. Unlike traditional DMS providers that offer one-size-fits-all solutions, we cater specifically to the evolving needs of EV manufacturers, used car dealerships and multi-brand workshops. For EV brands, most conventional DMS solutions lack battery management, charging infrastructure integration and telematics features. These are areas where we provide a significant edge. In the used car segment, our system simplifies inventory management, pricing intelligence and customer engagement, which many competitors struggle to optimise.

Another key differentiator is our scalable, cloud-based infrastructure that ensures real-time data access, automation and seamless integrations. While larger enterprise software providers focus on rigid, costly systems, we prioritise agility, efficiency and affordability, making digital transformation easier for dealerships of all sizes. Competition is strong, but our customer-first approach, deep domain expertise and innovation-driven solutions keep us ahead in this dynamic market.

How does Orbitsys plan to integrate new developments such as blockchain, AI, machine learning (ML), predictive analytics and voice-activated CRM features?

At Orbitsys, we are constantly evolving to stay ahead of industry trends. AI and ML are being integrated gradually, starting with specific modules like predictive analytics for leads management and automated customer insights. Over time, AI will become a core part of our system, enhancing decision-making, optimising workflows and improving customer engagement. We are also exploring blockchain for secure and transparent transactions, particularly in vehicle history tracking, warranty management and digital contracts. As connected vehicle technology advances, Orbitsys will integrate more closely with telematics systems to enhance the ownership experience through real-time vehicle diagnostics and proactive maintenance alerts. The goal is to streamline operations, reduce manual effort and enhance efficiency, ensuring that dealerships and OEMs can focus on what matters most – delivering an exceptional customer experience.

What are the automobile brands that Orbitsys is working with in India and overseas?

Orbitsys has been a trusted technology partner in the automotive industry since 1995, working with leading brands across segments. In the ICE space, we worked with Daewoo, Skoda, Isuzu, Keeway and Benelli, while in the EV segment, we are working with Omega Seiki, Revolt Motors, Lohia Auto, Amo Mobility and Montra in India. Beyond India, we have expanded our reach with BYD in Sri Lanka and the MAW Group in Nepal, supporting their Changan, Seres and Foton brands. Over 2,000 dealers and workshops have chosen to work with our system so far.

Lucas TVS: Strengthening Existing Avenues And Tapping New Streams

- By Bhushan Mhapralkar

- February 03, 2025

Shree Ranga, President – Automotive Business, Lucas TVS, spoke about the company’s product strategy and other developments on the sidelines of Bharat Mobility International Expo 2025.

What is exciting at Lucas TVS currently that would shape the future of automobiles?

Lucas TVS makes 12 to 15 million motors. It is the largest motor manufacturer in India. The company is producing many types of motors besides those of starters and alternators. This includes EPS motors, ABS motors, smart wiper motors, compressor motors, electric driven oil less vacuum pump and more. Lucas TVS also makes hub motors for electric two and three-wheelers. It has also taken to making batteries as allied products. Besides a vast portfolio of automotive products, the company is contemplating the manufacture of parts for home appliances. Focus is on parts that will it an edge as a manufacturer of various types of motors in terms of energy efficiency. Lucas TVS is entering into BLDC motors. The company has entered into sensors and is concentrating on controllers.

How are you looking to explore the electrification trend in automobiles?

Many of the customers in the four-wheeler segments are focusing on doing a lot of things internally where in the electric two and three-wheeler segments the manufacturers are looking at outsourcing. Lucas TVS is focusing on providing such manufacturers cutting edge technology solutions. The company is focusing on two and three-wheeler electric vehicles as the manufacturer of electric four-wheelers are getting involved themselves fully.

On the motors front for electric vehicles, how is the technology evolving?

PMSM has its own advantages and BLDC motor has its own advantages in terns of technology and application. A PMSM motor is more efficient than a BLDC motor and requires less magnet. BLDC motors, on the other hand, require rare earth magnets. PMSM is preferred for higher torque and higher power. Currently, the focus is on BLDC motor for the two and three-wheeler segments. Even the compressor motors that Lucas TVS makes are BLDC in nature. They also ensure high energy efficiency and are used in high end vehicles. A lot of effort is currently being put at Lucas TVS to enhance the energy efficiency of its products. Every product that the company is making is with an emphasis on best and highest energy efficiency irrespective of whether it is a motor or a generator. With a focus on providing smart and intelligent features, the stress is on providing mechatronic products as well. Lucas TVS is combining its skill sets in electrical and electronics engineering to provide mechatronic solutions. It wants to be looked upon as a provider of mechatronic solutions. The company is also open to work with any four-wheeler OEM in developing electric traction motor solutions. The market is transforming and the penetration of electrification in more in two and three-wheelers. It is therefore that Lucas TVS is working more rigorously.

Aren’t home appliances a curious case of diversification for Lucas TVS?

Lucas TVS knows what is a BLDC motor. Today, 70 to 80 percent of the ceiling fans employ induction motors at a time when sustainability and efficiency are the most spoken about terms. The focus at Lucas TVS therefore is to take to the common man a technology that will ensure the most efficiency in the form of a BLDC motor rather than an induction motor, which is less efficient. Almost 50 to 60 percent electricity can be saved. The push into non-automotive side of things will be under the brand name of TVS Green. Whatever appliances are used in a house and can ensure higher efficiency and less costs, Lucas TVS is focusing on under TVS Green. Considering the fact that a BLDC motor can be expensive to manufacture, what the company is looking at doing is to use its ability to produce motors at a large scale. This will enable it to offer such solutions as BLDC motor powered ceiling fans to the households at competitive prices. The price difference could be no more than 15-20 percent than that of an induction motor powered ceiling fan. TVS Green has started as one small division. The company is confident that it will grow quickly. This will also mark a B2C avenue as compared to many of our other business verticals which are B2B in nature.

From a supplier view point, how do you look at the electric two and three-wheeler business?

Today, most young people and women are choosing to buy electric vehicles. The market therefore is growing at a very fast pace. With the acceptability being quite good, it is the plug and play nature of the vehicles that is aiding their proliferation. The market for such vehicles will grow. There are players who were into motor manufacture for long and have exited. It is a highly competitive marketplace. What Lucas TVS is doing is to compete with key players. It is doing the necessary investments to grow in India at eight to 12 percent. This rate of growth is more than the growth rate of the industry. One may want to consider the fact that the transformation from ICE to electric vehicles that was envisages five years ago has not been attained. The attention of ICE side of business therefore continues in line with the philosophy: ‘Last man standing’. The company still makes parts for cars that are 30-year-old. Every customer is treated with the same respect. The growth has been very good and Lucas TVS continues to capture market share. Given the China plus one situation, the company has started to look at exports after finding that solutions from India are being looked at in Europe and US. Lucas TVS is working to address this demand. For the next fifteen years at least, ICE business for the company will continue to do well. On the other hand, Lucas TVS continues to increase its presence in various motor applications including sunroof motors, ESP, ABS motors etc. Lucas TVS – for two-wheeler segment – has been producing sensors and instrument clusters. Its group company makes magnetos, generators, clusters, fuel injection equipment etc. The latest product development includes the ISG, which is a starter-generator, electric two-wheeler ancillaries such as DC-DC convertor. Work is going on in the area of software with some companies in Europe but it is too early to speak about that.

You spoke about investments. What areas of the business are they regarding,

In the ICE business, investments of INR 2.5 billion to INR three billion have been made in the last three-four years. Another INR 1.5 billion to INR two billion investment has gone into the making of various motors such as the sunroof motors, ABS motors, tractor motors etc. In the last four-to-five years, Lucas TVS has invested around INR five billion.

So what is the growth outlook for the near to mid-term?

There are a lot of opportunities. The ambition is to move fast and tap them. On the exports front, India looks to be better off geopolitically. Lucas TVS has set up an office in Europe and US to tap those markets. Lot of enquires have been received. Lot of interest has been generated. A separate team is working on that front.

- Nagesh Joshi

- Nagesh JoshiExcellent write up and promising forecast sir. Looking forward to seeing more of the electrical vehicles taking lead Electric vehicles are game changers for sure. Charging stations for electric vehicles is indeed an opportunity for entrepreneurs to get involved. Entrepreneurs can be empowered by providing lucrative business opportunities to invest in charging stations and support them with ongoing running and maintenance.

Reply

Dr Amitabh Saran, Founder and CEO, Altigreen

- By Juili Eklahare

- March 23, 2023

Dr Amitabh Saran reveals Altigreen’s plans for the ASEAN market and talks about ESG goals and more.

As part of Altigreen’s plans to enter the passenger vehicle market, do you plan to hire fresh talent?

Sometimes start-ups land up doing a lot of things at the same time. The money runs out because a start-up starts with one problem and migrates to a completely different problem. Sometimes it starts adding all kinds of features to its products. For example, by entering the passenger space, we are clear that we cannot do this with the existing funds that we have. That’s because it’s clear that we need to have more teams, a different space etc. Also, we will be in a position to hire more talent and have a separate line entirely for passenger vehicles within the same factory. Besides, we have ensured that there will be ‘common-isation’ of platforms where skills can be achieved. So we are in the process of hiring talent.

What are your plans for charging solutions/infrastructure?

We are very clear that we are a vehicle OEM and do not build charging infrastructure. However, we do partner with a lot of charging companies who are building this infrastructure. We ensure that we are working with them, where we go hand-in-hand and everyone benefits. I have always believed that we need to do this as an ecosystem approach.

What are your plans for the ASEAN market?

We have always said that Altigreen focuses on India and the emerging markets. The emerging markets are South Asia, Africa and South America. The ASEAN market is very important to us, especially because one of our investors comes from Singapore, and they are going to help us a lot in our progress in ASEAN countries. Thailand, Indonesia, Philippines and Singapore are four places where we have already been seeing a lot of demand coming, in both passenger and cargo three-wheelers.

A major concern around EVs is high cost. How do you plan to tackle it?

To promote cell manufacturing and electronic component manufacturing in India, the government has created the PLI, wherein even other companies are participants. Each of them will be making cells, and I think they will start creating cells made in India and for Indian conditions, 2024 onwards. That will bring down cell prices and we will see more parity.

Is it that the younger generation, which is interested in purchasing EVs, is unable to do so on account of costs?

I don’t think so. Gen Z may be more inclined to exploring new things. But it’s not like every kid on the block is driving/riding an EV. I think it’s the convenience, which people find as a great alternative and as long as the use case is the same.

How is Altigreen meeting India’s ESG goals?

Over the last nine years, we have been doing a lot of R&D. Our focus was never on the paradigms of ESG or how we fit into it. But we ensure that we are doing everything to make sure that we are focusing on a sustainability paradigm. For example, if one looks at our motor design, they will see that we chose that there will be no magnets in it. Not just because the import of magnets should not be encouraged but also because we want to ensure that the motors are serviceable and manufacturable. Therefore, we have been very conscious about this. Moving forward, now that we are in expansion mode, we have an entire ESG section. Battery recycling is also something that we are working on. We do believe that the batteries that come out of EVs should not be thrown away. They have a very strong use case in solar and other areas, where we have already started working.

Comments (0)

ADD COMMENT