Greaves Cotton Engines Power European Micromobility With Ligier Partnership

- By MT Bureau

- November 18, 2025

Greaves Cotton, an engineering firm, has partnered with Europe’s Ligier Group, a manufacturer of light and heavy quadricycles. The collaboration will see Greaves’ Euro V+ certified 499cc REVO D+ diesel engines powering Ligier’s JS50 and Myli microcar models.

The engines, designed and manufactured at Greaves' facility in Chhatrapati Sambhajinagar, India, are integrated into Ligier vehicles sold across multiple European countries, including France, Italy, Spain and Germany. This partnership highlights India's increasing role as a supplier of regulatory-compliant automotive technologies globally.

The 499cc REVO D+ single-cylinder, 4-stroke diesel engine features electronic fuel injection and is designed for the light quadricycle, L6e category of vehicles.

The engine produces 6.0 kW of power at 3000 rpm and 26 Nm of torque at 1800–2200 rpm. The engine is claimed to deliver superior fuel efficiency, exceptional Noise, Vibration & Harshness (NVH) performance, and low friction. The engines met the stringent Euro V+ compliance norms through rigorous European-grade quality assurance, including cold-weather validation and lifecycle reliability assessments.

Parag Satpute, Managing Director and Group CEO, Greaves Cotton, said, “This partnership with Ligier is a proud milestone for Greaves Cotton, showcasing how a Made-in-India powertrain is driving European mobility solutions. It reflects our strong engineering capabilities, customer-centric approach, and commitment to delivering global quality standards from our Chhatrapati Sambhajinagar plant. As a trusted partner to OEMs worldwide, we continue to strengthen our comprehensive solutions driven approach that meet the demands of global OEMs for highest standards of performance, efficiency, and sustainability.”

Christian Dujardin, CEO, Ligier Group, said, “Our partnership with Greaves has been marked by outstanding collaboration and mutual trust. Together, we have succeeded in bringing to market the new 499cc REVO D+ engine - a modern, efficient, and reliable powertrain that perfectly meets today’s market expectations, regulatory standards, and customer demands. We are proud of the quality and fluidity of our exchanges throughout this project, which have allowed us to combine innovation and performance. Our teams continue to work hand in hand on future developments to stay one step ahead of the competition and uphold Ligier’s promise of always being at the forefront of innovation.”

Honeywell Supplies Battery Manufacturing Platform To Alabama Mobility And Power Center

- By MT Bureau

- March 05, 2026

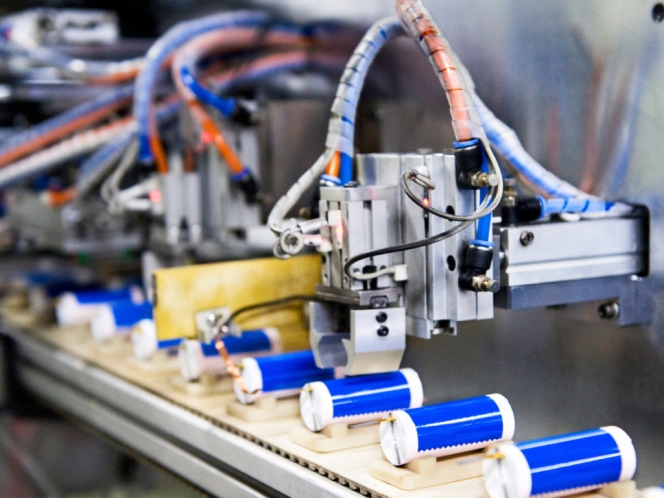

Honeywell has announced that its AI-powered Battery Manufacturing Excellence Platform (Battery MXP) is being integrated into the Alabama Mobility and Power (AMP) Center’s research lab at the University of Alabama. The platform is designed to automate battery production, improve cell yields and accelerate the startup of manufacturing facilities.

The AMP Center serves as a research hub for mobility and power technologies, including electric vehicle charging infrastructure and energy storage systems. The Honeywell platform will be used as the automation standard to train engineers and battery professionals in scaling production for industrial requirements.

Honeywell is also collaborating with FOM Technologies at the AMP Center to focus on the electrode production process. This phase of manufacturing is identified as a significant challenge in battery assembly; the partnership aims to use Battery MXP to automate this stage and improve the safety of cells for original equipment manufacturers (OEMs).

Key objectives of the integration include – workforce development, operational excellence and industry access.

The lab is scheduled to open in the second quarter of 2026. The deployment is intended to support the automotive industry while addressing energy requirements for data centres, grid stability, and regional electrification goals.

Mike Oatridge, Executive Director of the Alabama Mobility and Power Center, said, “The AMP Center was created to connect industry, academia, and state initiatives around the future of mobility and power. The deployment of Battery MXP supports Alabama’s automotive industry while advancing solutions for data center growth, grid stability, and the state’s long-term electrification and economic development goals.”

Russ Ford, President, Honeywell Process Automation Solutions, stated, “The rapid evolution of battery technology calls for a skilled workforce and advanced production capabilities at large scale, including comprehensive automation platforms powered by AI. AMP’s use of Battery MXP is poised to be a catalyst to empower the next generation of engineers in this important industry as it continues to grow.”

- JSW Motors

- Tata Indian Institute of Skills

- Tata IIS

- JSW Group

- EV

- Rupam Singh

- Skilling

- skill training

- Venguswamy Ramaswamy

JSW Motors And Tata Indian Institute Of Skills Partner For EV Manufacturing Training

- By MT Bureau

- February 26, 2026

JSW Motors, the new energy vehicle (NEV) arm of the JSW Group, has signed a Memorandum of Understanding (MoU) with the Tata Indian Institute of Skills (Tata IIS). The partnership establishes a technical talent pipeline for JSW Motors’ greenfield manufacturing plant currently under construction in Chhatrapati Sambhajinagar, Maharashtra.

The collaboration focuses on a co-developed curriculum covering EV systems, automation, welding, CNC operations, battery systems and manufacturing. JSW Motors maintains rights over curriculum validation and hiring to align with plant ramp-up schedules.

Tata IIS was selected based on its training infrastructure and experience in OEM engagement. The programme utilises application-based training designed for the requirements of electric vehicle production.

The initiative is part of a broader roadmap to create an EV-ready ecosystem including suppliers, vendors and dealer networks. JSW Motors eventually intends to establish an in-house training academy focused on mobility technologies and manufacturing.

Rupam Singh, Chief Human Resources Officer, JSW Motors, said, “At JSW Motors, skilling is not an HR function, it is a business imperative. As we build our manufacturing operations, we need people who are ready from Day One. The Tata IIS partnership gives us structured capability, relevant curriculum, and the execution rigour aligned to our timelines. This is a deliberate bridge as we work towards building our own world-class training academy.”

Venguswamy Ramaswamy, CEO Designate, Tata Indian Institute of Skills, said, “At Tata IIS, our mission is to solve the nation’s skill challenges by creating a next generation workforce that is not just job-ready, but future-ready. This partnership with JSW Motors is a significant step toward that goal. By designing bespoke programs in Advanced Manufacturing, we are equipping India's youth with the high-precision skills required to drive the next generation of automotive excellence and ensuring a robust, consistent talent pipeline for our industry partners.”

IR Power Launches Energy Recovery Solution For Industrial Applications

- By MT Bureau

- February 26, 2026

IR Power, a Scottish energy technology firm owned by MWNW Group, has introduced a standardised system designed to capture and reuse electricity wasted during industrial machine deceleration. The solution utilises a rental model where manufacturers pay through verified energy savings rather than upfront capital expenditure.

Industrial machines, such as automotive presses, conveyor systems and mixers, generate electricity when slowing down. In standard operations, this energy is typically dissipated as heat. IR Power’s technology claims that it captures this power and feeds it back into the factory grid for immediate reuse.

The system operates similarly to regenerative braking in electric vehicles. On machine clusters with frequent cycles, such as automotive press lines, the technology recaptures 10-20 percent of total electricity consumption. At current UK energy prices, this represents annual savings of GBP 50,000-100,000 per cluster.

Key features of the IR Power system include:

- Standardised Design: Three product sizes replace custom engineering, reducing technical complexity.

- Plug-and-Play Installation: Systems connect to existing equipment within hours without requiring modifications to the machines or production downtime.

- Equipment Agnostic: The technology integrates with hardware from any manufacturer, allowing for site-wide energy recovery networks.

- Fail-Safe Operation: Excess energy is routed to existing waste resistors if system capacity is exceeded, preventing manual restarts or shutdowns.

The launch comes as industrial electricity prices have risen to GBP 100-150/MWh. IR Power has adopted a zero-risk rental model to address adoption barriers. Under this framework, monthly fees are based on measured savings; if the system does not perform, the customer is not charged.

The company is initiating commercial deployments in Q1 2026, with a focus on tier-one automotive and construction materials manufacturing.

Richard Bradshaw, Founder and Managing Director, IR Power, said, "For years, energy recovery systems existed but didn't deploy at scale because they cost too much and put all the risk on customers. We've inverted that model completely. Our customers pay zero upfront – no capital expenditure, just operating expense. Installation takes hours with no production downtime. And here's the key: if our system doesn't save them money, we don't get paid; we take all the performance risk. The equipment lasts 15-20 years, so customers get over a decade of pure savings. The technology works – it always has. Our job was removing every barrier that prevented adoption: the cost, the complexity, the risk, and the disruption."

Zelio E-Mobility Opens New Plant In Cuttack to Expand Eastern India Operations

- By MT Bureau

- February 24, 2026

Zelio E-Mobility, a manufacturer of electric two-wheelers and three-wheelers, has announced the opening of a new manufacturing facility in Cuttack, Odisha. The plant is intended to support demand in Odisha and West Bengal while positioning the company for growth in southern India.

The commissioning of the Odisha facility, combined with optimisations at the existing Hisar plant in Haryana, has increased the company's total annual production capacity from 72,000 units to 180,000 units.

The Cuttack plant adds a capacity of 60,000 units per annum. Simultaneously, the Hisar facility has seen its capacity enhanced from 72,000 to 120,000 units through the installation of machinery and extended conveyor systems.

By locating production closer to the eastern markets, the company aims to reduce delivery timelines and logistics costs. Currently, shipping products from Haryana to the eastern region takes approximately one week.

The facility required an investment of under INR 30 million and is now operational. It is expected to create between 60 and 100 jobs for local individuals in production and operations. The company is currently in discussions with the Odisha government regarding incentives and support programmes.

Zelio E-Mobility clocked INR 1.34 billion in revenue in H1 FY2026, with net profit of INR 118.7 million. Recently, the EV company raised funds through SME IPO and has INR 360 million of unutilised funds, which it has earmarked for the current expansion. It aims to have over 337 dealerships across more than 20 states.

Kunal Arya, Managing Director, Zelio E-Mobility, said, “Eastern India has emerged as one of our strongest growth regions, with customers showing exceptional trust in our products. Setting up the Cuttack facility brings us closer to our riders and dealers, enabling faster deliveries, lower logistics costs and improved serviceability. Notably, this expansion marks an important step in strengthening India’s EV ecosystem and creating long-term value for our customers and partners.”

Comments (0)

ADD COMMENT