Hyundai Motor India’s Manufacturing Excellence Turns Metal To Marque Cars

- By 0

- April 05, 2020

HMI has 2 plants, established in 1998 and 2007. In the last 5 years both the plants have been augmented for capacity enhancement. This was possible as the assembly lines were initially designed for flexibility in augmentation, expanding to the needs of the following 15-20 years. That has always been the philosophy of Hyundai which is really paying off now; it becomes easier to execute improvements in all their projects.

Consider the body shop where components are accumulated to be worked upon. It is built on global bodyline concepts. Not only volume escalation but also increase in the number of models can be managed effectively. Every day the plant processes 395 tonne of steel coils, globally monitored by ‘Die Management’ system, to make cars with each one having on an average 4,500 spot weldings done by 4th gen robots. So far the company has manufactured more than 9 million cars using steel coils having a length that could cover the circumference of the earth 4 times. The intelligent weld management system generates about 30.6 million data points per day and the quality is controlled through real-time monitoring. Beginning with making one car every 4 minutes in 1998, the plant currently rolls out a car every 33 seconds.

Ganesh Mani S, Director, Manufacturing, HMI, told Motoring Trends that “we have 12 models now with 350 internal variants. The complexities in these are double challenges for us especially when we take to the next level. We were able to manoeuvre 3 or 4 models 3-4 years ago from a single line. Now it is 7 models. Volumes have also increased from 49 to 66 UPH (unit per hour). We have a two-pronged strategy; one is adding on volumes that can cater to the needs of consumers and, two, the capability for enhancement. Since we have our own Factory Automation companies in the automotive hub of South Korea, we have gone from Generation-1 to Generation-4 of robotics, which brings in a certain amount of flexibility and increase in the speed of execution. With CAFE and other norms, we need to make a model that is robust, which comes from the basic design and the way we build the product.”

Body shops are by and large 100 percent automated and therefore, the company was able to make them intelligent enough to understand, with the fourth generation robots. For every vehicle it is necessary to have resistant spot welding and for every spot there is a specification; this needs to be modified for each new model. The company has introduced intelligent timer controls, which is called MMDI - in the line before spot welding, it checks the number of components and their thickness and the level of current and voltage requirements.

Earlier they were pre-set, but now keep changing at every place. This gives twin advantages. The first is to have multiple components as technologies keep changing; aluminium may come in; high tensile steel welding has already come. At present the plant has about 400 robots with MMDI which have the capability to keep checking every time. Earlier it used to take 40 seconds to complete 30 spots; now within that TAKT time, it is able to make 50 spots increasing the speed of the line.

The second is having Intelligent Vision Control Systems. For instance, sealer has to be applied for vibration, harshness, noise, dust and rust prevention, strength, etc. The system monitors the route it has to follow and checks whether the job is being done properly or not. It ensures quality and traceability of the arrangement.

“Whenever we introduce a new model all we have to do is to make use of the carrier, a hardware that allows robots to move around and make the body parts. Only the carriers need to be replaced as the line operates depending on the types to be made. Earlier we had electric and pneumatic carriers to move across to lift the body and components while in the fourth generation robots at present the individual carrying capacity has been increased multiple times. The entire handling mechanism of conveyors, platforms, holding chains, etc has been replaced by just programming the robots which can handle them. All these save time and make the operation of the body shop more convenient,” he said.

A robot has shelf life of approximately 7 years; as and when replacements are due, new technologies are incorporated into the system. With so much innovation in robotics, the cost of robots is going down. Over the years the company has garnered expertise to the extent that a new robot can be commissioned in 48 hours, when it is needed to augment capacity. The industry average is 7 or 8 days. The supervisors and technicians can do the programming themselves, which also saves cost. Assembly shops have seven or eight major equipment and the company has been able to change or enhance the equipment that is augmented with VFD (variable frequency drive) as and when required. A fall back mechanism is in place to manage demand fluctuations. Robotic multi-skills and flexibility switchover help the line to go on smoothly. When not required some of the robots can be kept in sleep mode to save energy. Like managing absenteeism of people with multi-skills some of the robots can double up while the others can rest.

On the scope for improvement in enhancing UPH, Ganesh Mani said, “We can manage with this arrangement till 2021. We change regularly our upgradation on various models and try to eliminate defects at the design stage itself. We have a team working on every model and the results are ploughed back at the design stage to remove deficiencies. Also, there is the influx of technology in terms of inspection and robustness of the process. ‘Before’ and ‘After’ is 100 percent mapped for the sealers so there is no question of missing and moving across to the next stage.”

In the body shop the operator has all the available information in front of him. In the assembly shop everything is mapped digitally. The operator looks at a digital display to know which component he has to pick up; he also gets an audio message regarding assembly of parts for rare models. The company has created a Smart Innovation and Automation Team (SIAT) which is one step ahead in process monitoring to ensure that errors do not creep into the system; it makes certain that the operator does not commit a mistake. For instance the lid of containers holding the parts for the specific models will only open when required and at the right station.

Asked what happens if the operator has not taken the required number of parts like fasteners, he said, “We have more than 700 dynamic bolts and nuts that are fitted on the vehicle; any mistake in fitment would create havoc. We have HIVIS (Hyundai Integrated Vehicle Inspection System) which is a tool by itself. The torque values while tightening every nut are registered in the system. Any mistake made triggers an alarm and the vehicle will not be allowed to go to the next stage. The tightening process is monitored in real-time and is coupled with sign-off gate. When there is a process deviation, the system will not allow the car to roll out of the assembly line, thereby ensuring mistake-proof delivery. The system, developed at HMIL, is so intelligent that it is used all over the world. For example, when new trainees come, sometimes cross-threads happen; the torque goes very high and the value is reflected in the torque curve. This helps us take immediate corrective action. One of our engineers developed a ‘gyro metric gun’ that works on the straightness principle. It has a sensor inside, working on the principle of gravitational force; if there is any deviation of line it will not allow the operator to tighten the nut. This is a unique system, being used in all the 32 plants of Hyundai globally.”

How can variability happen? It can happen because of improper training; the company has taken care of this. The other variability is fatigue that could set in and result in the operator making a mistake. To prevent this there is REBA - Rapid Entire Body-movement Analysis - that can calculate the fatigue level in the individual. This information would help improve his comfort level. Meticulous planning has been done for all the stations, upgrading them from category A (with possibility of over 12 risk occurrences) to category D (less than 4), to bring down the risk level. On this platform there are many assist systems for the operator. The company is working on EXO skeleton which is a human-machine interface where a vest is provided to the operator giving him, among other things, elbow support. This makes the process easier and lighter; consistency always gets measured.

Ganesh Mani explained, “We also have vision camera system robotics that can capture 70 frames per minute. It compares the pictures with the original and if there is an error sends the message within a TAKT time of 40 seconds. This is our third layer of inspection. By and large our pass ratio is 100 percent; it is only a fall-back mechanism.”

Though the number of models assembled in one line has substantially increased, the company hopes that it can increase further. In assembly, there can be a high of as many as 240 different models, the maximum in a single line, he pointed out.

However, when the UPH in the body shop is increased it has to match the TAKT time of the assembly line as well. “In a lean production system we don’t want too much of a cushion in the other shops as that would prevent hidden problems from coming out. So we don’t go beyond one additional UPH in the previous shop; in between we have some amount of stock for body storage. Within that we manage our line. Every hour the body shop can create 1 more additional body in the same time required for assembly. In this way we can manage any breakdown or process delay up to 1 UPH. On a cumulative of 22 hours that we run, everyday a cushion of 22 bodies will be available to help us manage any kind of change,” he said.

Industry 4.0

About the possibilities of a smart factory Ganesh Mani said, “As part of our agile manufacturing process in our technologically advanced and digitalised factory we wanted to use Industry 4.0 in a big way. Our initiatives for this have started. We have found out that earlier in a body shop alone close to 1GB of data was generated; today it is 15GB a year from all the modules put together. The next stage is to integrate the data seamlessly and put them on display so that the operator who is multi-tasking can see them easily and monitor them thoroughly. This also helps in predictive maintenance which is the objective of big data. We use this in a 6-8 hour slot on Sundays when the assembly line does not work. Any change can be made then. This phase pre-empts impending failures; we use infrared mechanisms to do this. We also have vibration sensors fitted in the equipment that constantly monitor and give an alarm if something is likely to happen like heating up of the motors. We have a Data Analytics Team that looks into all these and takes preventive action. Today, more than 50 data scientists are working on the shop floor. By 2021 we want to integrate all the shops through this process so that we can predict what could happen. An example of how digitalisation in Industry 4.0 is helping us is in the breaking of equipment; whenever the vacuum levels start going up, the machine stops. To avoid this, by digitalisation we can constantly monitor the control limits to ensure that the equipment works in the programmed range. If it goes beyond the safe level, the system sends an SMS to the maintenance team. This helps the operator to plan and change the machine to a new area.”

Energy Conservation

HMI has completely switched over to LEDs, saving about 40 percent energy required for lighting. “Within 18 months we were able to get back the cost of the whole system. We always ensure that energy efficient motors are used. We are also very careful in using water, especially in places like Chennai where water is scarce. We are into hundred percent rain water harvesting. One mm of rain means a saving of 750 kl of water throughout the plant. We can manage 150 days of production without water from other sources; we are planning for complete independence,” he said. (MT)

Cars24 Introduces Refreshed Brand Identity

- By MT Bureau

- February 09, 2026

Cars24 has unveiled a refreshed brand identity, moving from its original transactional focus towards a car ownership ecosystem.

Founded in 2015, the company originally utilised an all-caps logo – CARS24 – to establish a presence in a fragmented market. The updated identity shifts the name to sentence case, Cars24, which the company states reflects maturity and a focus on trust.

The core of the redesign features an open circular logo. According to the company, this form represents the continuity of car ownership, where vehicles change hands and user needs evolve. The open shape is intended to signal flexibility rather than closure.

The brand has also replaced its traditional blue with a brighter shade. This ‘younger blue’ is intended to make the brand appear more attentive and human as it scales its operations.

The identity update was the result of over 1,200 hours of design and iteration. The goal of the project was to create a look that remains relevant as the company expands its services beyond buying and selling into broader ownership systems.

Vikram Chopra, Founder & CEO, Cars24, said, “When we started, being loud helped. But as the company and the team grew up, the work started speaking for itself. This change is about reflecting who we are today, calmer, more human and focused on earning trust over time.”

Maruti Suzuki India Increases Rail Dispatches To 585,000 Units, Up 18% In 2025

- By MT Bureau

- February 09, 2026

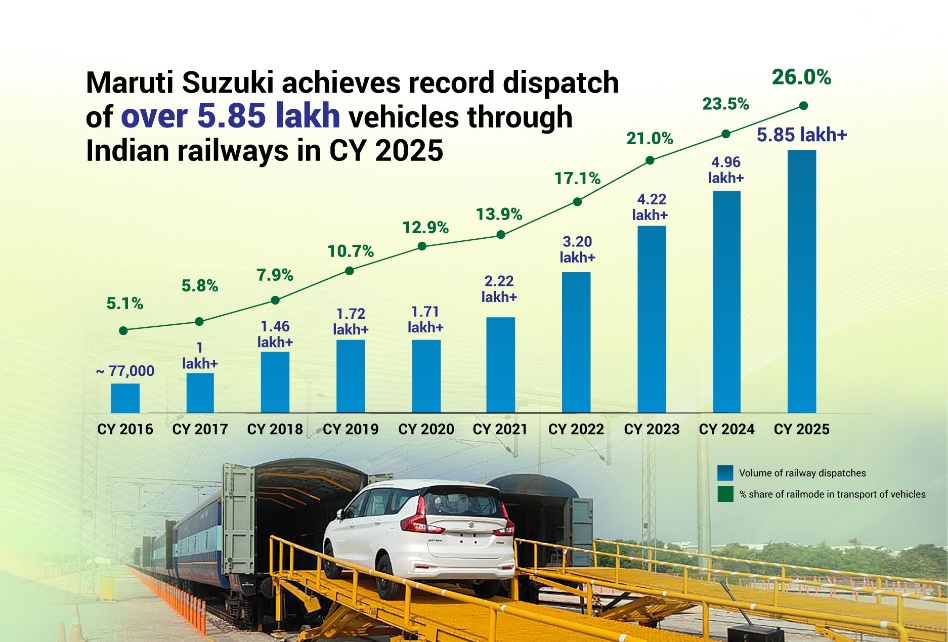

Maruti Suzuki India, the country’s largest passenger vehicle manufacturer, has reported the dispatch of over 585,000 vehicles using the railway network in CY2025, which marked an 18 percent growth compared to CY2024.

Over the last decade, the company's use of rail for outbound logistics has risen from 5.1 percent in 2016 to approximately 26 percent in 2025. The shift aims to reduce carbon emissions, oil imports and road congestion.

In 2025, Maruti Suzuki India inaugurated an in-plant railway siding at its Manesar facility. The company also became the first manufacturer to dispatch vehicles to the Kashmir valley using the railway bridge over the Chenab river.

Combined dispatches from in-plant sidings at Gujarat and Manesar accounted for 53 percent of the company's total rail volumes during the year. The manufacturer currently employs 45 flexi-deck rakes, with each train capable of transporting approximately 260 vehicles.

Combined dispatches from in-plant sidings at Gujarat and Manesar accounted for 53 percent of the company's total rail volumes during the year. The manufacturer currently employs 45 flexi-deck rakes, with each train capable of transporting approximately 260 vehicles.

The company was the first automaker to receive an Automobile-Freight-Train-Operator (AFTO) license in 2013. Since FY2014-15, it has transported more than 2.8 million vehicles to 600 cities using a hub-and-spoke model.

Hisashi Takeuchi, MD & CEO, Maruti Suzuki India, said, “The year 2025 marks our highest-ever rail dispatch, with over 585,000 units. During the year, we strengthened our green logistic efforts through two landmark events – the inauguration of India’s largest automobile in-plant railway siding at our Manesar facility and second was we dispatched vehicles by rail to Kashmir valley through the world's highest railway arch bridge over Chenab river, a first by any automobile manufacturer. Our mid-term goal is to increase rail-based vehicle dispatches to 35 percent by FY 2030-31, contributing to India’s net-zero ambition by 2070. Maruti Suzuki India has adopted a comprehensive ‘Circular Mobility’ approach to sustainability, aiming to reduce its carbon footprint across the entire vehicle lifecycle – from design and production to logistics and end-of-life vehicle (ELV) management.”

- Toyota Motor Corporation

- TMC

- Koji Sato

- Kenta Kon

- Japan Automobile Manufacturers Association

- JAMA

- Keidanren

- Japan Business Federation

Kenta Kon Appointed President & CEO Of Toyota Motor Corp, Koji Sato Transitioned As Vice-Chairman & CIO

- By MT Bureau

- February 09, 2026

Japanese automotive major Toyota Motor Corporation (TMC) has announced a restructuring of its executive leadership and Board of Directors. The changes to the executive structure will take effect on 1 April 2026, while board appointments remain subject to the 122nd Ordinary General Shareholders' Meeting.

Koji Sato, currently President and Member of the Board of Directors, will transition to Vice Chairman and the newly created role of Chief Industry Officer (CIO). Kenta Kon, currently Operating Officer, has been appointed as the incoming President and Chief Executive Officer.

Under this structure, Sato will oversee industry collaboration and external relations. Kon will lead internal management, focusing on company-wide reforms and value chain integration.

The board cited the need for decision-making in a changing environment as the primary driver for the move. Sato’s role as CIO reflects his responsibilities as Chairman of the Japan Automobile Manufacturers Association (JAMA) and Vice Chair of Keidanren (Japan Business Federation). These positions require him to lead policy proposals and industry-wide coordination to maintain international competitiveness.

The appointment of Kenta Kon as CEO follows his tenure as Chief Financial Officer, where he managed efforts to lower break-even volumes and improve the company's earnings structure. His experience at Woven by Toyota is expected to support the company’s transition into a mobility-focused organisation.

The board determined that Sato’s external commitments as a coordinator for the Japanese automotive industry required a structure that separates industry-level leadership from day-to-day corporate operations. The proposal for the new personnel structure was approved during a board meeting on 6 February.

The transition aims to improve Toyota’s earning power and strengthen partnerships within and beyond the automotive sector.

Force Motors Posts Best-Ever Third-Quarter Performance

- By MT Bureau

- February 06, 2026

Force Motors Limited reported its strongest third-quarter performance to date, with double-digit revenue growth and sharply higher profit margins for the three months ended December 31 2025, extending its record run in the 2025–26 financial year.

The Pune-based vehicle maker recorded standalone revenue of INR 21.55 billion in the quarter, up 13 percent year on year. Earnings before interest, tax, depreciation and amortisation rose 63 percent to INR 4.01 billion, while profit before tax, excluding exceptional items, increased 91 percent to INR 3.28 billion.

Including exceptional items, profit before tax rose to INR 5.39 billion, more than three times the level a year earlier, while profit after tax climbed 266 percent to INR 4.03 billion. The company reported no debt at the end of the quarter.

For the first nine months of the financial year, revenue rose 14 percent to INR 65.83 billion. EBITDA increased 43 percent to INR 11.45 billion, while profit before tax after exceptional items nearly doubled to INR 11.42 billion. Profit after tax for the period rose 153 percent to INR 9.38 billion.

Domestic volumes grew 25 percent during the nine-month period, supported by demand across the Urbania, Traveller, Gurkha (defence variants), Monobus and Trax platforms. Export volumes increased 30 per cent year on year, led by growth in light commercial vehicles, special vehicles and utility vehicles.

The Traveller platform-maintained segment leadership, with market share consistently above 70 percent, the company said.

Prasan Firodia, managing director of Force Motors Limited, said, “The performance in the third quarter reflects steady demand across our core product segments and improved operating leverage as volumes have scaled through the year. Growth has been broad-based, supported by continued traction in shared mobility, defence-related applications, and export markets.”

He added that demand visibility remained healthy in intra-city and inter-city passenger mobility, with institutional and fleet customers continuing to prioritise purpose-built platforms.

“Given the momentum we have gained and with Q4 underway, we are confident of closing the year on a strong note and delivering our best financial performance to date,” Firodia said.

Comments (0)

ADD COMMENT