A look Behind the Scenes: ECU Testing with XCP support

- By 0

- June 15, 2020

In most cases, it is actually sufficient to look at the ECU’s inputs and outputs to functionally test a component (Figure 1). However, this becomes difficult when state machines are used in the ECU. Their current states can only be derived indirectly by their effects at the ECU’s outputs. In the case of sensors whose values are not transmitted over the network system, it is also very difficult for the test engineer to localize errors to the software interface. From outside the ECU, it is not clear exactly where the sensor value was incorrectly processed.

Different methods that offer access to internal ECU data are used, depending on the phase of ECU development. In early phases, for example, internal ECU values are often output in so-called “reserved development messages” (Figure 1). For the functional developer at a supplier, this is an effective and quick method that precisely targets a specific objective. However, these supplemental messages must be removed for later development phases, especially for system integration and series production. They induce additional bus load, and in the worst case they might even collide with messages of other system components. Another way to access internal values is through diagnostics (Figure 1). Some information is available directly via diagnostics, e.g. diagnostics offers access to fault memory. Special diagnostic services are also provided to read the required values from memory. The advantage here is that a standardized access method is used. The only precondition is full integration of the diagnostic driver; this is generally provided in today’s ECUs. The disadvantage of this method is that a lot of unnecessary diagnostic protocol information is transmitted along with the actual measured values, and this adds load to the network system interface. A data flow analysis of many values is not possible, especially since the measured values do not contain time stamp information.

XCP For Test Access

If network interface load needs to be kept low, an alternative is to use a calibration protocol. Originally, such protocols were developed for the ECU calibrator. They let calibrators modify parameters or characteristic maps in the ECU to optimize their algorithms. With the XCP protocol standardized by ASAM, the user can read individual values directly from the ECU as needed. The protocol can also periodically supply a defined set of measured values from the ECU via so-called Data Acquisition (DAQ) lists. The XCP protocol was defined for efficient provision of data over the network medium. As an example, after configuration the DAQ lists can be transmitted in response to a single identifier from the test system. In addition, measurement times of the DAQ lists can be synchronized to internal ECU processes. Automated test systems place similar requirements on the system. Use of the XCP protocol makes it possible to integrate internal values in test sequences without excessive loading of the ECU or the network system used. Another reason that a widely used standard like XCP is ideal is that it is very easy to configure in the tool chain. All necessary information is already in the A2L file such as internal program memory locations with their names and communication parameters. Depending on the development environment, the A2L file is either automatically generated, or it may need to be generated in a separate step from the linker-map information. In the test tool, the user only has to configure this file once for each ECU used in the test. In a second step, the user selects the symbols needed for the test sequences from the A2L file.

CANoe Option .AMD/XCP

Option .AMD/XCP supplements the CANoe test tool from Vector with the convenient option of reading and writing internal ECU values. Besides supporting the XCP standard, it also supports the previous protocol CCP. Once the A2L file has been configured and the necessary values selected, CANoe automatically acquires them and maps them as system variables. The user can then use these variables in any of the testing tasks. Besides offering access to ECU inputs and outputs, they also provide an in-depth look into the ECU’s memory (Figure 2).

In simple analysis tasks, users can display the data in the Trace or Graphic Window and use panels to evaluate the results. For more complex test sequences, CANoe’s Test Feature Set offers extensive options for creating test cases and automatically evaluating them. For example, this enables checking of the Network Management state machine for correct functionality. The necessary stimulation is performed in the CANoe rest-of-bus simulation, and the ECU’s reaction is not just measurable on the network; it is directly measurable in the ECU over XCP. The effort required to execute test cases is also significantly reduced, e.g. for test cases that require sensors. The test system writes the sensor values directly to memory cells in the ECU over XCP. This eliminates the need to connect and control original sensors at the ECU inputs – a demanding task. The ECU is notified that the sensor and associated hardware driver have measured the values correctly. The same approach can be used in the other direction. Here it is assumed that the output stage and actuator have been tested and accepted. In this case, the test system measures the value that the application prescribes to the driver stage over XCP.

Access With Large Quantities Of Data

If large quantities of data need to be exchanged between the test system and the ECU in a test case, or if especially quick processes need to be monitored, an XCP connection over a CAN network is no longer effective. In such cases, direct access to the ECU’s debug interfaces is recommended. This could be implemented via a NEXUS or JTAG interface, for example. These protocols directly access the ECU memory − partly without load on the microcontroller. Taking this approach, the user can quickly read out very large quantities of data from the system without loading the network and the ECU.

Vector VX hardware, for example, offers direct access to an ECU’s NEXUS or JTAG interface (Figure 2). Since this hardware communicates with the test system via XCP-on-Ethernet, integration in CANoe is as easy as integration for XCP access over CAN. Combining VX hardware with the CANoe test system further improves test system performance, without any negative effects on the communication medium. (MT)

NB: Oliver Falkner is group leader at Vector in product management of the Networks and Distributed Systems product line. Views expressed are personal.

Carraro Group Meets Indian Officials In Milan

- By MT Bureau

- June 06, 2025

Carraro Group’s leadership – including Ettore Francesco Sequi, Chairman of Carraro India, and Tomaso Carraro, Vice Chairman of Carraro Group and Carraro India – had a meeting with Union Minister Piyush Goyal and Indian Ambassador to Italy Vani Sarraju Rao in Milan, Italy, underscoring the deepening industrial collaboration between Italy and India, particularly in the off-highway, agriculture and construction equipment sectors.

The discussions reaffirmed Carraro Group’s long-standing commitment to India, which began in 1997. Under the motto ‘Think & Make in India’, the company has focused on developing localised solutions for the Indian market, including advanced 4WD drivetrain systems that enhance agricultural productivity and farm mechanisation. These technologies play a crucial role in supporting food security by improving efficiency for farmers, enabling higher yields and addressing global demand for sustainable food production.

Carraro India has set an ambitious growth target, aiming to increase its turnover from the current EUR 200 million to EUR 350 million by the fiscal year 2028-29. To achieve this, the company plans to expand its manufacturing facility in Pune, reinforcing its production capabilities and strengthening its supply chain within India. This expansion aligns with India’s ‘Make in India’ initiative, promoting local manufacturing and job creation while catering to both domestic and international markets.

The engagement highlights India’s growing appeal as a manufacturing and investment destination for European companies, particularly in the agricultural and construction machinery sectors. It also reflects the broader economic and technological partnership between India and Italy, fostering innovation, skill development and industrial growth.

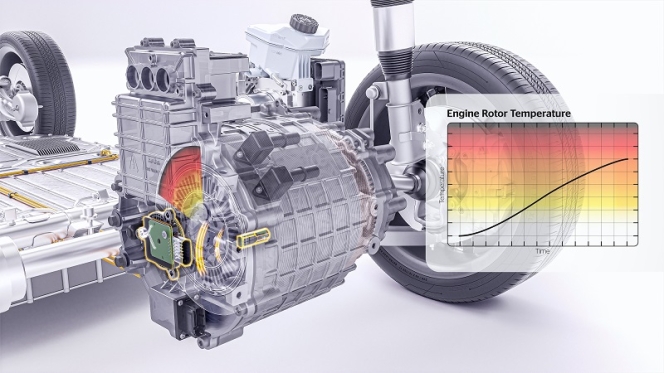

Continental’s New Sensor Tech Measures Heat In EV Motors, Claims To Reduce Rare Earths To Protect Magnet

- By MT Bureau

- June 04, 2025

German automotive technology giant Continental has developed a new sensor technology that is said to significantly enhance the efficiency and sustainability of electric vehicle (EV) motors.

For the first time, their new e-Motor Rotor Temperature Sensor (eRTS) directly measures the temperature inside permanently excited synchronous motors on the rotor itself.

This innovative approach delivers substantially more precise measurement results than current software-based temperature simulations, drastically reducing the tolerance range from 15deg Celsius to a mere 3deg Celsius. The enhanced accuracy offers a dual benefit for vehicle manufacturers: it enables them to reduce the reliance on costly rare earth elements used to boost magnet heat resistance and simultaneously improve potential motor performance. This, in turn, paves the way for greater sustainability in EV production.

The eRTS is a key development from Continental's E-Mobility Sensors (EMS) product centre, which is dedicated to creating advanced sensor technologies for electric vehicles.

Bin Huo, Head of Passive Safety and Sensorics (PSS) segment, Continental, said, "With less resource consumption and lower costs, eRTS sensor technology is advantageous over current solutions. This innovation shows that investing resources and focusing expertise in our product centre was absolutely the right decision. We will continue to successively expand our EV sensor portfolio."

Higher Measuring Accuracy

The eRTS system comprises two distinct components: a wireless mote temperature sensor unit positioned close to the magnet within the EV motor and a wired transducer element situated outside the motor, connected to the inverter control.

Rotors operate under extreme conditions, with temperatures potentially reaching up to 150deg Celsius. Consequently, precise monitoring and control of heat development in EV motors are paramount. Presently, heat development is not measured directly but is instead calculated based on data from the stator temperature sensor, phase current measurements and environmental variables. This indirect method results in a tolerance range of up to 15deg Celsius. To safeguard magnets from demagnetisation due to excessive heat, expensive rare earth elements are typically used to cover this entire tolerance range and ensure sufficient heat resistance.

The significantly greater measuring accuracy of the eRTS, which reduces the tolerance range to just 3deg Celsius, presents car manufacturers with new design possibilities and freedom in permanent magnet synchronous EV motors.

A considerable proportion of costly rare earth materials, which would otherwise be required to account for the wider tolerance range for safety reasons, can now be saved. Furthermore, the improved accuracy offers the intriguing prospect of enhancing motor performance by pushing the operational limits closer to the actual temperature threshold.

Christoph Busch, Lead – Product Centre, Continental, said, "Our E-Mobility Sensors product centre aims to increase efficiency and sustainability in electric vehicles. The eRTS technology is a prime example of this: reducing the use of rare earths contributes to a more sustainable supply chain, especially given that the number of EVs is expected to greatly increase in the coming years and decades. In combination with other sensor technologies, such as the e-Motor Rotor Position Sensor, it can even act as a system solution to create synergies that can save car manufacturers money and effort."

Ultrasound Technology

The eRTS's two components, the mote element and the transducer element, work in tandem. The mote temperature sensor unit measures the temperature directly at the target area, as close as possible to the magnet. Crucially, the wireless mote draws its energy solely from the wired transducer, which is connected to the Electronic Control Unit (ECU) and simultaneously provides the transducer with its measuring data. The transducer is located outside the EV motor on the chassis and transmits temperature information to the inverter control via a communication interface. Both the mote and transducer communicate using Piezo ultrasound, which also facilitates the energy supply to the mote.

- Stargate

- Stargate UAE

- Cisco

- OpenAI

- Nvidia

- Softbank Group

- Oracle

- Jensen Huang

- Masayoshi Son

- Larry Ellison

- Sam Altman

- Chuck Robbins

- Peng Xiao

- G42

- Abu Dhabi

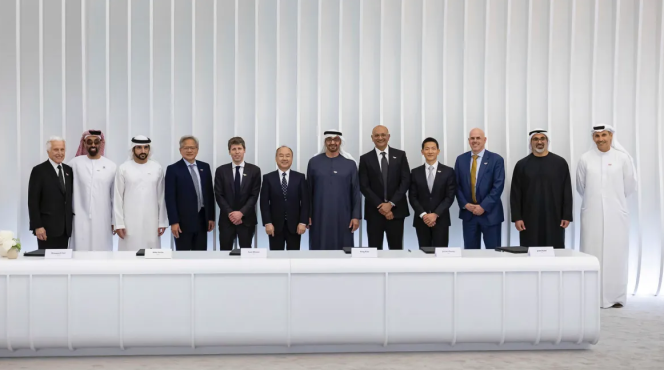

Global Tech Giants Unite To Launch Stargate UAE, Ushering A New Era Of AI Collaboration

- By MT Bureau

- June 02, 2025

In a landmark development for artificial intelligence and global technological partnerships, G42, OpenAI, Oracle, NVIDIA, SoftBank Group and Cisco have joined forces to launch Stargate UAE, a next-generation AI infrastructure cluster set to operate in Abu Dhabi.

The announcement, made in the presence of President Sheikh Mohamed bin Zayed Al Nahyan, highlighted UAE’s commitment to driving cutting-edge innovation on the world stage.

The launch event witnessed the attendance of Sheikh Khaled bin Mohamed bin Zayed Al Nahyan, Crown Prince of Abu Dhabi, Sheikh Hamdan bin Mohammed bin Rashid Al Maktoum, Crown Prince of Dubai and Deputy Prime Minister & Minister of Defence and Sheikh Tahnoon bin Zayed Al Nahyan, Deputy Ruler of Abu Dhabi and Chairman of the Artificial Intelligence Council, alongside prominent dignitaries and senior officials.

Stargate UAE, a 1-gigawatt compute cluster, will be constructed by G42 and operated by OpenAI and Oracle. NVIDIA will provide its cutting-edge Grace Blackwell GB300 systems, while Cisco contributes AI-ready connectivity and zero-trust security frameworks. SoftBank Group will also play a crucial role in the initiative. Once operational, Stargate UAE will deliver exceptional AI infrastructure, scalable compute resources, and ultra-low latency for inferencing, enabling powerful AI applications across industries. The first 200-megawatt cluster is slated to go live in 2026.

Designed to fuel scientific discovery, industry innovation and economic growth, Stargate UAE will support sectors including healthcare, energy, finance and transportation. It forms the cornerstone of the newly announced UAE–US AI Campus, a 5-gigawatt AI hub spanning 10 square miles in Abu Dhabi – the largest deployment of its kind outside the United States. Powered by a combination of nuclear, solar and natural gas sources, the facility will prioritise sustainability and low-carbon operations. It will also feature a science park to nurture talent, advance research, and promote sustainable computing solutions.

The UAE–US AI Campus builds upon the ‘US-UAE AI Acceleration Partnership’, a framework unveiled last week by the U.S. and UAE governments to foster safe, secure and responsible AI technologies. As part of this initiative, UAE entities will expand their digital infrastructure investments in the U.S., including projects like Stargate U.S., aligned with the ‘America First Investment Policy.’

Peng Xiao, Group CEO, G42, said, “The launch of Stargate UAE is a significant step in the UAE–US AI partnership. As a founding partner, we’re proud to work alongside institutions that share our belief in responsible innovation and meaningful global progress. This initiative is about building a bridge – rooted in trust and ambition – that helps bring the benefits of AI to economies, societies, and people around the world.”

Sam Altman, Co-founder and CEO, OpenAI, said, “By establishing the world’s first Stargate outside of the US in the UAE, we’re transforming a bold vision into reality. This is the first major milestone in our OpenAI for Countries initiative – our effort to work with allies and partners to build AI infrastructure around the world. It’s a step toward ensuring some of this era’s most important breakthroughs – safer medicines, personalised learning, and modernised energy – can emerge from more places and benefit the world.”

Larry Ellison, CTO and Chairman, Oracle, said, “Stargate pairs Oracle’s AI-optimised cloud with nation-scale sovereign infrastructure. This first-in-the-world platform will enable every UAE government agency and commercial institution to connect their data to the world’s most advanced AI models. This landmark deployment sets a new standard for digital sovereignty and demonstrates how nation states can harness the power of the most important technology in the history of humankind.”

Jensen Huang, Founder and CEO, NVIDIA, said, “AI is the most transformative force of our time. With Stargate UAE, we are building the AI infrastructure to power the country’s bold vision – to empower its people, grow its economy, and shape its future.”

Masayoshi Son, Chairman and CEO, SoftBank Group, said, “When we unveiled Stargate in the US with OpenAI and Oracle, we set out to build an engine for the next information revolution. Now, the UAE becomes the first nation beyond America to embrace this sovereign AI platform, proving the global nature of this vision. SoftBank is proud to support the UAE’s leap forward. Bold investments, trusted partnerships, and national ambition can create a more connected, more joyful and more empowered world.”

Chuck Robbins, Chair and CEO, Cisco, said, “Cisco is proud to join Stargate UAE to advance groundbreaking AI innovation in the UAE and around the world. By embedding our secure AI-optimised networking fabric for this international deployment, we're building smart, secure and energy-efficient networks that will turn intelligence into impact at global scale.”

- Maruti Suzuki India

- Japan External Trade Organisation

- JETRO

- Dr Tapan Sahoo

- Takashi Suzuki

- Hisashi Takeuchi

- Accelerator

- Incubation

- Mobility Challenge

- Nurture

Maruti Suzuki and JETRO Partner to Boost India-Japan Startup Collaboration

- By MT Bureau

- May 29, 2025

Maruti Suzuki India, the country’s largest carmaker, has announced a new partnership with the Japan External Trade Organisation (JETRO) aimed at fostering innovation and creating business opportunities for startups in both India and Japan.

The collaboration, formalised through a Memorandum of Understanding (MoU), seeks to bridge the startup ecosystems of the two nations.

The MoU was formally exchanged by Dr Tapan Sahoo, Executive Officer, Digital Enterprise, Maruti Suzuki India and Takashi Suzuki, Chief Director General, JETRO India, Hisashi Takeuchi, Managing Director & CEO, Maruti Suzuki India, was also present during the signing.

As per the understanding, Maruti Suzuki India and JETRO will work together to help Indian startups gain access to Japan's innovation landscape, while Japanese startups will similarly have the opportunity to explore India's vibrant startup ecosystem.

Beyond access, the partnership will facilitate networking and participation for these startups in relevant industry events and activities, connecting them with potential partners. Indian startups selected through Maruti Suzuki's four innovation programs – Accelerator, Incubation, Mobility Challenge and Nurture – will be eligible to participate in these initiatives. Japanese startups, on the other hand, will be able to explore the Indian market through JETRO's support.

Hisashi Takeuchi, said, "Through our multi-format innovation programs, we have been engaging with startups in India to co-create technology-driven solutions relevant to the automobile manufacturing and mobility space. We see great potential in Indian startups, and with this MoU with JETRO, we will be able to provide a platform for these promising startups to explore the Japanese business landscape."

Takashi Suzuki, Chief Director General, JETRO India, said, "Maruti Suzuki stands as one of the finest examples of the successful partnership between India and Japan. With this MoU, we are creating opportunities for even more fruitful business collaborations between our two nations. This MoU aims to foster innovation, drive economic growth, and further strengthen the deep-rooted ties between India and Japan."

Comments (0)

ADD COMMENT