Audi's eAWS Turns SUVs Into Quick-Change Artists

- By MT Bureau

- August 29, 2020

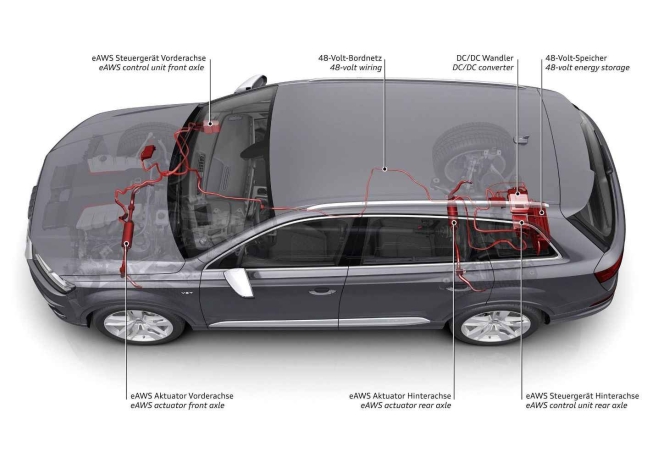

How do you provide a large SUV with sporty road-holding properties and minimal body roll without impairing ride comfort? Audi has resolved this by implementing electromechanical roll stabilization (eAWS). Assisted by the 48-volt onboard electrical system and powerful actuators, the stabilizers on the front and rear axle can be actively controlled according to the driving situation. As a result, the models retain their high level of ride comfort in straight-line driving. By contrast, in cornering and load alteration situations, they impress with enhanced lateral dynamics combined with minimal body roll. The technical advantages of Audi’s electromechanical solution: it is energy-efficient, operates in near-real-time and is virtually maintenance-free due to the absence of hydraulic elements.

What challenges do large SUV models pose to chassis engineers?

Customers of larger SUVs are thrilled by their many practical elements – from ample space in the cabin to cutting-edge chassis technologies to powerful engines and advanced control and assistance systems. Plus, an SUV can deliver superb performance off paved roads. Due to their design, these vehicles feature a higher curb weight and a higher center of gravity. This means that the body of an SUV leans more toward the outside in cornering than it does on models with a lower center of gravity.

What technology counteracts body roll and body movements?

In cornering, the body leans toward the outside due to the centrifugal forces, in other words, the wheel on the outside of the corner goes into jounce travel while the one on the inside of the corner goes into rebound – the vehicle rolls around its longitudinal axis. Torsionally flexible anti-roll bars between the left- and the right-hand side of the axle are proven means of compensating for this effect. They help reduce the body’s tendency to roll by applying reverse torsion torque to the suspension on the outside and inside of the corner, thus counteracting the body’s tendency to roll. This passive suspension component has the same effect in both cornering and straight-line driving. However, an effect that is desirable in cornering may impair ride comfort in straight-line driving on roads with bumps or potholes on one side of the surface. While passive solutions can reach their limits here, Audi has resolved this by means of electromechanical roll stabilization. Using sensors to capture and detect the situation, the system is designed to intervene with pinpoint precision only when less body roll is desired. Thus, the spring rate of the stabilizers on uneven and straight roads is lowered to a basic level and the spring and damper forces act by and large independently on the left- and right-hand wheels.

How does electromechanical roll stabilization work?

A conventional stabilizer operates passively. In other words, it just balances the suspension movements on both sides by means of mechanical coupling. By contrast, electromechanical roll stabilization can be specifically controlled. The system consists of two stabilizer halves per axle, with an electric motor operating between them on both the front and rear axle. It can rotate the stabilizer halves in opposite direction of each other and thus generate torque that counteracts body roll torque – individually for each wheel. As a result, it reduces the body roll angles and actively supports them against the physical effects of the driving situation. The system receives its commands via control units on the front and rear axle, which are part of the Electronic Chassis Platform (ECP). The ECP is the central brain of the chassis. Within milliseconds, it matches a variety of parameters such as speed, ride height, roll and pitch movements of the car, the friction coefficient of the road surface, the current driving condition such as under- or over-steer, plus the data of the chassis systems involved. From this input, the system calculates the ideal responses for the integrated components and adjusts them quickly and precisely to each other. The required electrical energy is supplied to the eAWS by a powerful 48-volt onboard electrical system. Within milliseconds, the system calculates suitable actuation values for the stabilizers. The electric motors deliver their power output via three-stage planetary gearboxes, with torque levels of up to 1,200 Nm being generated at the stabilizers.

What is “Vorsprung durch Technik” in the case of an electromechanical solution?

The 48-volt system enables an immediate system response even at low speeds. Latency between the sensors detecting body roll and the response by the electric motors is just a few milliseconds. Unlike hydraulic solutions, the eco-friendly electromechanical system does not require oil circuits and is maintenance-free. It is even able to recuperate energy by capturing suspension impulses on its electric motor, converts them into electrical energy and stores it in the lithium-ion battery of the onboard electrical system. The electromechanical solution uses energy more efficiently as well. In contrast to hydraulic circuits, it does not have to store and provide pressure.

How does the driver benefit from the system?

The system helps reduce the body’s tendency to roll, provides a sportier and more confident handling impression and emphasizes the versatile character of the large SUV models. It can actively distribute roll torque to the front and rear wheels and influence the car’s intrinsic steering characteristics such as the tendency to under- or oversteer. The Audi drive select driving dynamics system offers various setup options for this. Electromechanically active roll stabilization imparts to the driver a dynamic and precise feel in a variety of situations and enables enhanced handling characteristics. It is one of various systems that perfect the dynamism of the top-end models of the Q range. The Audi Q7, SQ7, SQ8 and RS Q8 models with their controllable stabilizers respond to the driving situation precisely as expected by the driver. On uneven road surfaces, the body movements are reduced while ride comfort increases. In sporty driving and at high cornering speeds, the car feels more stable and at ease. It pushes itself into a bend in the road. Audi has deliberately selected a setup that does not completely neutralize the roll angle but continues to impart an authentic feel of the driving dynamics situation.

How is the system on the racetrack and the real world?

Impressive proof of the influence of the controllable stabilizers was provided by race and test driver Frank Stippler in the fall of 2019. As part of the development work for the Audi RS Q8 the professional race driver, who in 2019 won the 24-hour race at the Nürburgring for the second time with Audi, set a new lap record for production SUVs. He managed to drive the 20.832-kilometer distance of the race track in the Eifel region in just 7:42 minutes. Forty percent of global Audi customers who have ordered a large Audi SUV model have chosen the option of electromechanical active roll stabilization. (MT)

ZF, BMW Sign Long-Term Supply Agreement For Drive Technologies

- By MT Bureau

- February 03, 2026

German tier 1 supplier ZF Friedrichshafen and the BMW Group have entered into a long-term supply agreement for passenger car drive systems. The contract, valued at several billion euros, extends until the late 2030s.

The agreement focuses on the supply and continued development of the 8-speed automatic transmission (8HP). The partners aim to support low-emission mobility and maintain technological flexibility during the industry transition.

A central component of the partnership is the technical evolution of the 8HP transmission kit to meet the requirements of electrified drives. The development will focus on increasing efficiency and performance for future vehicle concepts.

Mathias Miedreich, CEO of ZF, said, “Together with BMW, we are sending a strong signal for innovation, efficiency, and sustainability in an industry undergoing dynamic change. This agreement highlights the strategic importance of our 8-speed automatic transmission as a key technology for the transformation of drive systems.”

The duration of the contract provides both ZF and BMW with planning stability in a changing market. ZF aims to strengthen its position as a system supplier while reducing risks through close collaboration with the carmaker.

Sebastian Schmitt, Head of ZF's Electrified Drive Technologies division, explained, “The new agreement with BMW shows how important long-term planning horizons are for technological advancements. It creates clarity and stability for both companies and enables us to align the next generation of the 8HP specifically toward efficiency, performance, and long-term viability.”

Leapmotor Selects Aumovio For Safety Technologies

- By MT Bureau

- February 02, 2026

Aumovio has entered a supply agreement with Chinese electric vehicle manufacturer Leapmotor to provide safety components for the carmaker’s B and C platforms.

Several models within Leapmotor’s B platform now utilise Aumovio's long-range radar, electric parking brake and airbag control unit (ACU). Models on the C platform, including the C10, C11 and C16 SUVs, feature the latest generation of the MK C2 one-box brake system, alongside the long-range radar and ACU.

The project was completed with a development cycle approximately one-third shorter than traditional automotive timelines. Aumovio attributed its speed to ‘local-for-local’ strategy in China, where the company operates 20 sites and employs around 10,000 staff. In 2024, Aumovio held a 14 percent share of market revenue in the region.

The supplied technologies include:

- MK C2 Brake System: A unit combining the master cylinder, electronic brake system, and brake booster. It is produced locally in Shanghai.

- Long-Range Radar: A sensor with a detection range of up to 280 metres, used for driver assistance across both platforms.

- Airbag Control Unit (ACU): Integrated with crash satellite sensors, these components are manufactured in Changchun.

Boris Mergell, Head of the Safety and Motion business area at Aumovio, said, “Pairing ‘China speed’ with ‘German quality’ technologies helped us to support a rapid roll-out with our latest safety technologies. This underscores Aumovio’s course towards an adaptive powerhouse that works flexibly and closely with customers to innovate. It also shows that we continue to strengthen our customer relationships in the important market China.”

The partnership supports Leapmotor’s international presence. The B10 and B05 models, which feature Aumovio's ACU and radar technology, were showcased at the IAA 2025 in Munich as part of the manufacturer's European entry.

LTTS Secures Multi-Year Deal From Automotive OEM For Engineering And R&D

- By MT Bureau

- January 28, 2026

Bengaluru-headquartered ER&D company L&T Technology Services (LTTS) has announced a multi-year engagement within its mobility segment from an automotive manufacturer. The agreement involves software, connectivity and digital engineering services across vehicle technology domains. This win follows the company’s investments in R&D labs and mobility infrastructure designed for programs with global manufacturers.

The engagement covers mobility engineering capabilities, including embedded systems, digital platforms, verification and validation, cloud integration and cybersecurity. LTTS intends to use its engineering expertise and delivery frameworks to support the customer's technology roadmap.

At present, LTTS operates 22 design centres and 100 innovation labs globally.

The agreement strengthens the partnership between LTTS and the automotive manufacturer in the area of mobility engineering. The company provides design, development, and testing services across the mobility, sustainability, and tech segments.

Alind Saxena, Executive Director and President, Mobility and Tech at L&T Technology Services, said, “We are proud to deepen our partnership with the valued customer through this strategic engagement. LTTS brings together domain-led engineering, secure development practices and excellence in global delivery to accelerate the future of premium mobility. The win reflects the trust placed in our teams and our commitment to delivering world-class engineering at scale”.

Valeo And NATIX Network Partner To Develop Open-Source World Foundation Model

- By MT Bureau

- January 25, 2026

French technology company Valeo and NATIX Network have announced a partnership to develop a multi-camera World Foundation Model (WFM). The project combines Valeo’s research in artificial intelligence and generative modelling with NATIX’s decentralised physical infrastructure network (DePIN) to create an open-source platform for autonomous driving and robotics.

The initiative aims to move beyond perception-based models by creating a system capable of predicting future states and reasoning about physical interactions in a four-dimensional environment. The model will be trained using NATIX’s data network, which has collected 600,000 hours of video data across the US, Europe and Asia over seven months. This data provides the multi-camera inputs necessary for the spatial perception required by autonomous vehicles and robots.

The partnership builds upon Valeo’s existing open-source frameworks, VaViM (Video Autoregressive Model) and VaVAM (Video-Action Model). While these frameworks were previously trained primarily on front-camera datasets, the integration of NATIX’s multi-camera network expands the AI’s field of vision to 360 degrees.

Under the open-source framework, the partners will release models, datasets and training tools. This approach is intended to allow the research community to fine-tune models and benchmark physical AI across various driving conditions and geographic regions. The collaboration seeks to accelerate the deployment of end-to-end AI models by learning from real-world edge cases captured by vehicles in operation.

Marc Vrecko, Chief Executive Officer, Valeo’s Brain Division, said, “Since our creation in 2018, Valeo’s AI research center has been at the forefront of AI research in the automotive industry, especially in the fields of assisted and autonomous driving. Our goal has always been to advance mobility intelligence safely and responsibly. By combining Valeo’s generative world modeling research expertise with NATIX’s global multi-camera data, we are accelerating both the quality and the accessibility of next-generation end-to-end AI models, enabling the research community to build upon strong open models.”

Alireza Ghods, CEO and Co-Founder, NATIX, added, “WFMs are a once-in-a-generation opportunity — similar to the rise of LLMs in 2017–2020. The teams that build the first scalable world models will define the foundation of the next AI wave: Physical AIs. With our distributed multi-camera network, NATIX has a clear advantage of being able to move faster than large OEMs.”

Comments (0)

ADD COMMENT