The global shortage of semiconductors or chips in the aftermath of the Covid-19 led pandemic has eased as per a report by Crisil. A development that led most automakers to cut down production significantly and postpone the launch of new models or to put them to production through 2020, 2021, 2022 and a good part of 2023 has finally eased to iron out any supply chain disruptions that may be there.

Expected to address and improve predictive demand forecast, the better availability of chips should enable better production schedules. By FY2025-26, Crisil analysts are of the opinion that demand-supply dynamics should be more balance with additional manufacturing capacities getting commissioned.

With the chips possessing distinct electrical properties that make them the cornerstone of all electronic equipment and devices, it is the auto industry that has come to use them for a variety of functions as automobiles turn increasingly software driven. While the computer and communication equipment (C&C) segment consumes roughly 63 percent of the chips produced, the auto industry consumes roughly 13 percent of them. The other industrial segments consume about 12 percent.

With new developments such as autonomous and EVs, the use of semiconductors in automobiles is only slated to rise. With passenger vehicles the recipient of most technological innovations ahead of other segments such as two-wheelers, three-wheelers and commercial vehicles, it should not come as a surprise that they consume about 1,500 chips on average – the highest among all automobile types.

As more advanced electronic features are incorporated, the use for chips increases. The electric passenger vehicles, for example, use almost twice as many chips as internal combustion engine (ICE) passenger vehicles do. The improving supply and slowing demand for computers and mobile phones is therefore looked upon as a blessing in disguise for automobiles and their manufacturers.

Anuj Sethi, Senior Director, CRISIL Ratings, mentioned, “The chip shortage faced by Indian passenger vehicle makers is easing, with current availability at 85-90 percent of total requirement. The production loss on account of the chip shortage, which had halved to about 300,000 PVs on-year in fiscal 2023, is estimated to have further declined to under 200,000 PVs by the end of September 2023.”

Most passenger vehicle manufacturers are currently operating at near optimal capacity utilisation due to stronger-than-anticipated demand. New orders to be serviced remains high at about 700,000 units at the end of September 2023.

The easing of chip shortage should help automakers honour new orders with better prediction and faster production. Global automobile demand, severely impacted by the Covid-19 pandemic, made a strong recovery in the latter part of FY2021-22. It caught automobile manufacturers off guard as they had not placed substantial orders for chips.

The surge in demand for personal computers, laptops and mobile phones, driven by work from home, virtual learning and remote healthcare services, led to a significant chip procurement challenge for the automakers.

Geographically, the chip ecosystem is skewed, with western nations dominating chip architecture, design, manufacturing equipment, specialised materials and chemicals. Semiconductor fabs1 on the other hand are concentrated in eastern nations, such as Taiwan and South Korea.

Given the criticality of chips in the defense and aerospace industries, the United States and the European Union have offered incentives of about USD 100 billion for localisation of semiconductor fabs. As a result, many global players are slated to spend about USD 360 billion towards setting up new facilities, which would be operational by 2025 and 2026.

In the Indian context, demand for chips will continue to increase over the medium term, driven by the gradual rise in EV adoption and growing demand for advanced feature-laden ICE vehicles.

Maurice Meijer Appointed As TIP Group’s First Chief Digital and Information Officer

- By MT Bureau

- March 06, 2026

TIP Group has announced the appointment of Maurice Meijer to the newly established position of Chief Digital and Information Officer. This strategic role underscores the increasing significance of digital innovation, data management and technology in advancing the company’s long-term Strategy 2030 objectives. As TIP expands its footprint as a comprehensive transportation services provider across 17 European nations, the integration of digital solutions is viewed as essential to fostering operational efficiency, business growth and superior customer engagement.

In his capacity as CDIO, Meijer will lead the formulation and execution of the group’s digital and technological roadmap. His responsibilities encompass overseeing digital platforms, enhancing data analytics capabilities, managing IT infrastructure and strengthening cybersecurity protocols. The goal is to build resilient, scalable systems that align with TIP’s future ambitions.

Meijer joins with a robust background in board-level technology leadership. He previously served as Chief Technology and Information Officer at Nederlandse Loterij, where he spearheaded major digital transformations across various brands and platforms. Prior to that, he held key roles in digital strategy, product development and operations within both the technology sector and public institutions. Additionally, he is involved in supporting early-stage tech startups as an investor and founding partner.

His educational credentials include executive programmes at Nyenrode University and INSEAD, along with a degree in international business management. Meijer is recognised for blending strategic commercial insight with practical technological expertise.

Arjen Kraaij, President & CEO, TIP Group, said, “Digitalisation is central to TIP’s future success. With Maurice, we are bringing in a strong business and technology leader who will help us simplify complexity, strengthen our digital foundations and accelerate execution across the Group. His leadership will be instrumental as we translate our Strategy 2030 ambitions into practical, value-creating solutions for our customers and our teams.”

Meijer said, “I’m really looking forward to joining TIP at this important stage in its journey. With strong foundations, great people and clear ambitions under Strategy 2030, there’s a lot to build on. At the same time, we’re ready to take the next step by accelerating our shift towards more digital solutions. By embracing digital, data and AI in a focused and practical way, we’ll turn opportunities into solutions that truly improve the customer experience and make day-to-day work simpler, smarter and more effective for both our customers and our teams.”

Holyvolt Completes $73 Million Acquisition Of Wildcat Discovery Technologies

- By MT Bureau

- March 06, 2026

Swedish battery technology firm Holyvolt has finalised the acquisition of US-based materials specialist Wildcat Discovery Technologies in a deal valued at USD 73 million. The transaction consists of a combination of cash, equity and deferred milestone payments.

The merger integrates Wildcat’s High Throughput Platform (HTP) for material synthesis with Holyvolt’s water-based screen-printing production processes. The combined entity intends to operate as a technology development partner for the automotive, aerospace and energy storage sectors, offering licensing and pilot-scale production services.

Wildcat’s HTP system allows for the simultaneous screening of thousands of material combinations. This method is reported to be up to 10 times faster than standard research and development protocols, generating terabyte-scale datasets suitable for machine learning and AI applications.

Key capabilities of the integrated group include:

- Material Discovery: Use of combinatorial chemistry to identify optimal battery systems.

- Manufacturing Process: Holyvolt’s water-based processing serves as a replacement for conventional organic solvent-based slurries.

- Data-Driven Optimisation: Integration of structured datasets into AI models to accelerate development cycles.

- Sustainability: Focus on cobalt- and nickel-free materials to reduce capital requirements and supply chain dependencies.

The acquisition follows a EUR 20 million funding round for Holyvolt. The new group aims to address production costs and supply chain independence in Europe and North America by combining chemistry expertise with modular manufacturing technology.

Mathias Ingvarsson, Founder & CEO, Holyvolt, said, “The acquisition of Wildcat is a perfect complement to our intended strategy of developing new technologies for the battery industry. Holyvolt is focused on developing new processes to make batteries cleaner and more affordable, and Wildcat has been pursuing the same goals via materials development and better chemistry. Combined, we are building what we believe is the most compelling technology to deliver on these objectives.”

Mark Gresser, President and CEO, Wildcat Discovery Technologies, stated, “The Wildcat team is thrilled with this acquisition by Holyvolt. Mathias and team are very thoughtful with regard to their objectives in the battery industry, and recognise the value that Wildcat’s High Throughput Platform can deliver to our combined company and the industry at large. With Holyvolt’s vision and financial backing, Wildcat can finally unlock the true potential of high throughput combinatorial chemistry for battery materials.”

Prof. Peter Schultz, Founder, Wildcat Discovery Technologies, noted, “With Holyvolt, we can do for batteries what high throughput and AI have done for drug discovery.”

BYD Unveils Second-Generation Blade Battery With Flash Charging Tech

- By MT Bureau

- March 06, 2026

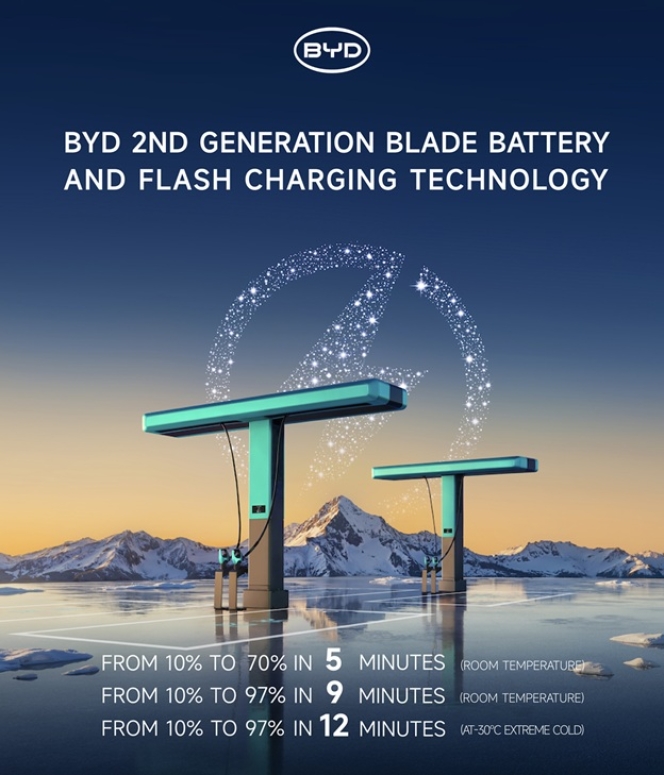

Chinese automotive major BYD has revealed its second-generation Blade Battery alongside FLASH Charging technology, aimed at improving charging speeds and battery performance in low temperatures.

The system achieves a claimed charge from 10 percent to 70 percent state of charge (SOC) in five minutes, and reaches 97 percent in nine minutes. In temperatures of -30deg C, the charging time from 20 percent to 97 perrcent increases by three minutes compared to performance at room temperature.

The second-generation Blade Battery increases energy density by 5 percent over the previous version. To manage thermal loads during rapid charging, BYD integrated a ‘Lithium-Ion High-Speed Channel’ and a thermal management system.

Key technical specifications include:

- Range: The Denza Z9GT, equipped with this battery, achieves a range of 1,036 km.

- Thermal Management: Full-spectrum systems to regulate heat dissipation.

- Safety Standards: The battery has passed national safety tests regarding puncture and thermal runaway.

- Infrastructure: A world-leading single-connector output of 1500 kW.

BYD plans to build 20,000 FLASH Charging Stations in China by end-2026, with a global rollout scheduled to follow. These stations will feature a pulley-based charger design to improve user ergonomics and keep cables off the ground.

To manage the high-power requirements of 1500 kW charging, the stations use energy storage systems to buffer the demand, reducing the load on the local power grid.

Horse Powertrain Debuts Groundbreaking ‘Amorphous Motor’ Technology

- By MT Bureau

- March 05, 2026

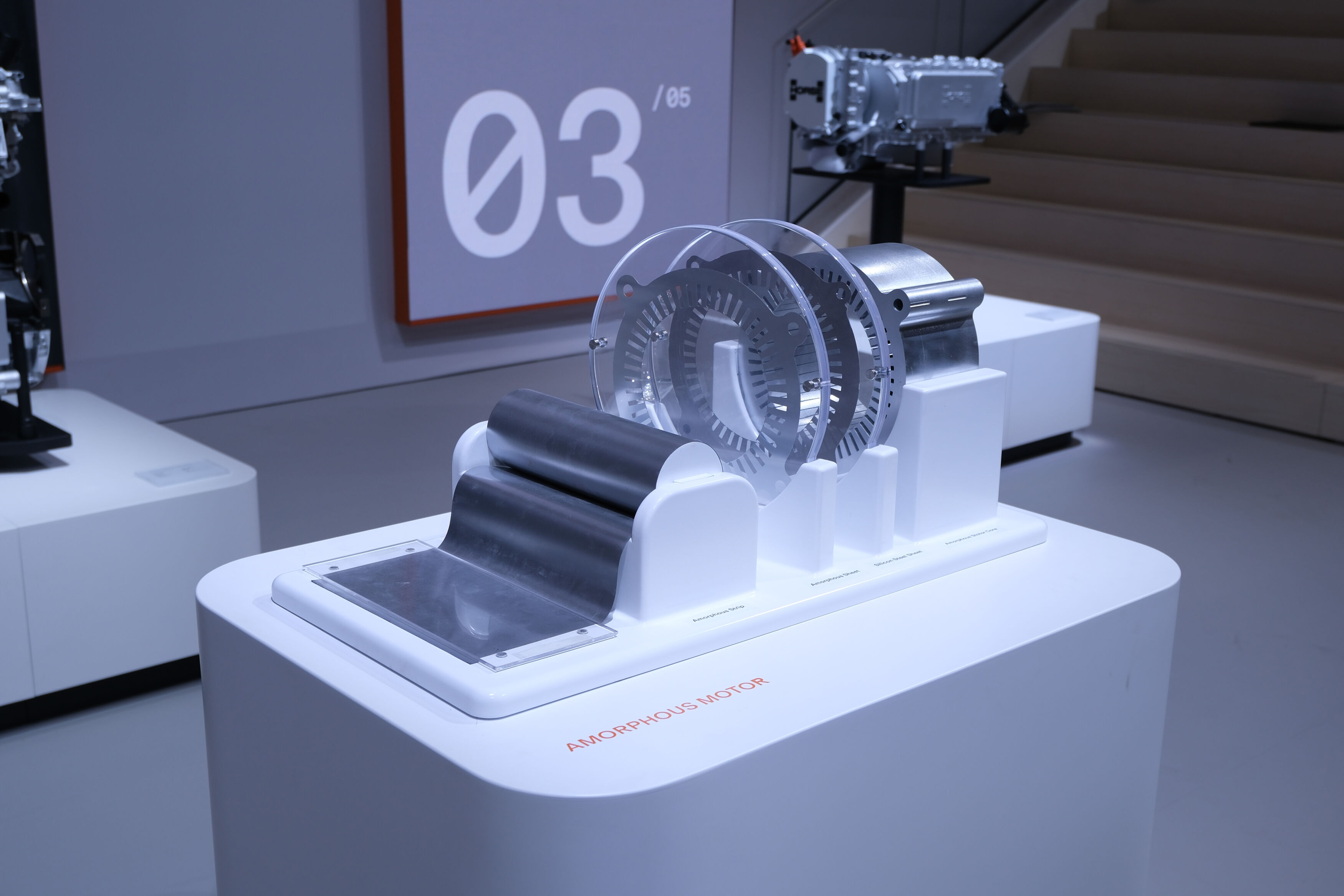

Horse Powertrain, a global leader in advanced and low-emission powertrain solutions, has unveiled its new Amorphous Motor technology, marking a significant step forward in hybrid transmission systems. The innovation was introduced to the public for the first time at the IAA Summit 2025.

Central to the motor’s design is the use of amorphous steel, a material known for its exceptional strength, durability and magnetic properties. This material allows the company to significantly reduce the thickness of the steel laminations used in the motor’s stator. While traditional motors use steel sheets of a standard thickness, the layers in the Amorphous Motor are only 0.025 mm thick, roughly one-tenth of the conventional standard.

This ultra-thin construction, combined with the material’s high conductivity, leads to a 50 percent reduction in stator iron losses compared to similar designs. Consequently, the motor achieves a record-setting efficiency of 98.2 percent, all while delivering a maximum output of 140 kW and 360 Nm of torque.

The practical impact for hybrid vehicles is a one percent improvement in overall fuel and energy efficiency. This reduction in consumption supports automotive manufacturers in their efforts to develop a new wave of lower-emission models. This breakthrough is part of a broader strategy by Horse Powertrain to advance hybrid and combustion technologies through a technologically neutral approach to decarbonisation. The company’s global capabilities, which include 17 manufacturing sites, five research and development centres and a workforce of 19,000, continue to drive this series of high-efficiency innovations.

Ingo Scholten, Deputy Chief Technology Officer, Horse Powertrain, said, “This latest innovation demonstrates Horse Powertrain’s continued commitment to research and development, providing suppliers and OEMs with the tools to raise the bar on when it comes to fuel economy and emissions performance. The Amorphous Motor is an ideal tool to power a new generation of high-efficiency range extended EVs, hybrids and plug-in hybrids, ensuring these technologies continue to play a substantial role in automotive’s decarbonisation journey.”

Comments (0)

ADD COMMENT