By T Murrali:

Freudenberg Performance Materials India (FPMI), part of Freudenberg Performance Materials (FPM), a global manufacturer of technical textiles, nonwovens and fibre, has been operational in India with a production site in Chennai since 1998. It has plans also to cater to the modern commercial vehicles by expanding its product portfolio.

Globally, FPM manufactures high-performance technical textiles and nonwovens for a wide range of applications including automotive, building materials, clothing, hygiene, wearables and healthcare. The FPM products / materials for automotive industry customers include mechanically bonded nonwovens for car headliners, trunk and rear seat coverings that are characterized by abrasion resistance. Besides, it caters to the OEMs with tuft backing for carpets and moulded under-body panels and wheel liners. FPM products make driving more efficient, climate friendly and comfortable. Nonwovens are lighter than woven variants and, therefore, support a more economic driving style. They help absorb sound, ensure pleasant climate inside the vehicle and help save fuel and reduce CO2 emissions.

Globally, FPM manufactures high-performance technical textiles and nonwovens for a wide range of applications including automotive, building materials, clothing, hygiene, wearables and healthcare. The FPM products / materials for automotive industry customers include mechanically bonded nonwovens for car headliners, trunk and rear seat coverings that are characterized by abrasion resistance. Besides, it caters to the OEMs with tuft backing for carpets and moulded under-body panels and wheel liners. FPM products make driving more efficient, climate friendly and comfortable. Nonwovens are lighter than woven variants and, therefore, support a more economic driving style. They help absorb sound, ensure pleasant climate inside the vehicle and help save fuel and reduce CO2 emissions.

For some of the products FPMI is an extended arm of the manufacturing locations of FPM outside India. The global company has manufacturing facilities in Germany, Korea, China, Japan, and the US; these are the locations where it has automotive manufacturing hubs.

Speaking to this publication, G Sivasailam, Managing Director, FPMI, said, “Essentially our R&D is in Germany, Korea, China, Japan, and the US which we carry to all other consuming countries. We see the Indian market as very promising in the near future. We want to warm up the market with the services and supplies from other locations, which we are currently doing. Supplies are coming in on a duty-free basis which is used in vehicles for exports. For example, many companies are exporting quite a lot to Latin America; we cater to that by supplying headliners. We also do the sun-roof for many Japanese & Korean based car manufacturers for their export models. Currently the domestic market is catered to by a few suppliers in Mumbai and Gurugram.”

There is substantial value addition for the OEMs and end-customers with the application of non-woven products in which case cost is not a criterion. Still what is preventing the OEMs here from getting them from the global companies like Freudenberg? Sivasailam said, “We use a three-denier fibre which is very fine compared with the six-denier used in the market. So the starting point itself is totally different. Secondly, the kind of binders and latex that we use are all CFC-free and they are also bio-decomposable. At the end of the day a consumer for an entry level car will look at the price. But for the premium cars, the price may not matter much.

Speaking on the advantages he said the NVH values of this product are superior to what is available in the market but the end-consumer finds it a little isometric to the value he is getting. For instance, sound absorption by the headliner is much higher than that of one made out of six-denier but the percentage difference is not necessarily the reason for making this a premium product, the consumer is unable to comprehend the difference. With the evolution of vehicles from ICE to Electric, there are enough opportunities for companies like FPM because the noise created by the IC engine nullifies the other noises while in the EV operation is silent. Therefore, “we see a big opportunity there. That is one particular area where innovation has been directed to by Freudenberg. Not only on headliners but also on back trays, hood liners, floor mats etc. We are coming up with composites which are lighter with longer life for a carpet, offering Lutraflor (Freudenberg technology) floor mats that are lighter and stronger. They have high abrasion resistance that remains despite perpetual usage. The weight here is reduced substantially and the back trays are super absorbent of noise. The hood liners take care of the temperature as well as the noise. These are the areas where we have come up with lighter material, meeting the requirements,” he said.

These products reduce the weight of the four big mats that weigh about 3.5 to 4kg by 25 percent. Overall, there is about 10-15 percent reduction over the conventional products. That’s the reason why today a lot of patronage is shown to these products; as of now they are used only in the C or D segment cars. In India it will take a little more time to reach these segments. Customer awareness level is still not high in India. However, when it comes up, the company would be able to offer a competitive product, considering the economies of scale, which would match the market trends, he said.

UV Rays Impact

Normally, UV rays raise temperature. When they are absorbed by the seats or any component temperature builds up and the a/c in the car is made to work more to maintain the temperature. There is also fuel loss. To cut it down it is necessary to reduce the amount of UV light that goes into the car which would enhance the mileage of the vehicle; passengers also will be benefited as UV rays are not good for the skin.

FPM has developed a composite material for the under-body shield to which patent is pending. “In most countries the under-body shield is metal; we are trying to replace it with a non-woven backed composite that would have the tenacity to take stones and everything hitting it at high speed. Straightaway, the weight proposition will change,” he said. Would that not affect the safety of the vehicle since, for stability, lower centre of gravity is key and this can be achieved by placing heavier stuff under body of the car? Sivasailam said the solution is to support only on the engine side; under-body shield is normally on the engine side so that stones don’t fly into the engine and hit the other parts. When there is lighter material on the front of the vehicle it actually enhances mobility. What is unique is the way the composite is made, the technology and construction; and the amount of tenacity it brings to the product to increase longevity. It’s a 100% recyclable material as well with weight saving up to 40%.

Business Opportunities

On the new opportunities for FPM, Sivasailam said, “We are also having battery separators; they are undergoing development as high storage batteries. It avoids catching fire which mitigates the risk to a great extent because of the ceramic coating. That is where e-mobility will make big commercial success. The other possibilities for the company to explore in India are the commercial vehicles, which are now getting smarter and better as vehicle makers give importance to the interiors; so there is an opportunity for them to get into this business. Even today most accidents take place due to driver fatigue. If that can be minimised it would help. The touch on the headliner or on the seat-back, everything is important. Haptic feeling is not given importance in India as of now. That is something that will be very good with a three-denier head liner. “We are also working on better acoustic properties on the trims. We have a product called Evolon which is a fine fibre technology, spun drawn with very good NVH property. We are working with Evolon in some automotive companies where we feel it can give much superior noise control,” Sivasailam said. (MT)

Multimatic Installs First VI-grade HyperDock System In North America

- By MT Bureau

- February 20, 2026

VI-grade has announced the installation of its HyperDock cockpit at Multimatic’s Vehicle Dynamics Centre in Novi, Michigan. This deployment marks the first instance of HyperDock technology in North America. The system upgrades an existing DiM250 driving simulator, installed in 2020, into a platform capable of simultaneous vehicle dynamics and NVH (Noise, Vibration, and Harshness) development.

The HyperDock consists of a carbon-fibre cockpit designed to increase stiffness and reduce inertia. By removing the traditional top disk in favour of a direct actuator interface and integrated vibro-acoustic feedback, the system allows engineers to assess ride, handling and acoustics within a single environment.

The upgrade introduces ‘full-spectrum’ simulation, which bridges the gap between high-frequency vibration testing and low-frequency motion cues.

- Construction: Lightweight carbon-fibre frame.

- Interface: Direct actuator connection to minimise signal delay and mechanical loss.

- Feedback: Integrated tactile and audio systems for vibro-acoustic realism.

- Application: Simultaneous tuning of vehicle handling and interior cabin noise.

Peter Gibbons, Technical Director – Vehicle Dynamics, Multimatic, said, “After evaluating the VI-grade HyperDock Full Spectrum Simulator cockpit at the SimCenter Udine over a year ago, Multimatic quickly realized that it would provide a significant step forward in the fidelity of all DiM applications, from road car ride tuning to race car limit handling. The overwhelmingly positive responses from Murray White, Technical Director of Vehicle Development at Multimatic, and Dirk Müller, professional race car driver, affirmed Multimatic’s decision to upgrade to HyperDock. The added immersion, superior tactile feedback, and audio advancements have moved the goalposts well beyond our expectations. Multimatic looks forward to continuing to leverage the impressive capabilities of HyperDock over the coming years.”

Alessio Lombardi, Global Sales Director – Simulation, VI-grade, added, “With the addition of HyperDock, Multimatic now benefits from full-spectrum simulation capability, expanding the scope of development activities that can be performed on an already well-established simulator platform. This installation represents an important milestone for VI-grade, as it brings HyperDock technology to North America for the first time.”

- ADAS 2026 Show

- Autonomous

- Driving

- Developments

- Magna

- Mobileye

- Renault

- Ampere

- Mobileye

- Tata Motors

- ARAI

- Aayera

- demo

- live

- conference

- inauguration

- automotive

ADAS 2026 Show Looks At Autonomous Driving Developments

- By Bhushan Mhapralkar

- February 20, 2026

Postponed from December 2025 to February 2026, the ADAS Show 2026 by Aayera was a combination of stalls where diverse players from the field of ADAS or autonomous driving highlighted their latest developments. There were live demo sessions that saw the use of passenger vehicles, trucks and dummies to highlight the technological prowess in the field.

Held at ARAI’s newest testing and certification facility for ADAS and other modern automotive technologies at Takwe (Pune), the show saw experts speak about the autonomous future in panel discussions, presentations etc. Live demos highlighted progress on the computing and vision front; on the software front, underlining certain zest.

In his inaugural address, Dr Reji Mathai, Director, ARAI, spoke about the motive behind setting up an ADAS testing facility at Takwe. Observing that tracks never give returns to draw attention to the decision of setting up an ADAS testing track at Takwe (the newest yet by ARAI), Dr Mathai informed that ARAI participates at the UN level in regulation forming.

Dr Mathai; Elie Luskin, Vice President – India and China, Mobil Eye, and Nina Roeck, Vice President – Software Engineering (Drive & Comfort), Ampere (Renault Group), were united in their expression about India’s unique traffic and driving conditions. The trio stressed on localisation of ADAS system parts such as sensors; on local engineering and development, and on local testing and validation.

“In India, the conditions are different and the effort therefore is to focus on perception, alerts and interventions that consider the local driving condition,” said Roeck.

Asserting that India’s expanding auto market has disproportionately low ADAS. Luskin explained, “ADAS would become mainstream as India’s GDP per capita grows.

Apurbo Kirty, Head – Electrical & Electronics, ERC, Tata Motors, focused on advanced driver assistance in CVs in his address. He referred to road challenges in India, road accident statistics and the challenges for ADAS implementation in terms of SAE autonomy levels, regulations like GSR 834 and how ADAS is a necessity rather than just a tech upgrade.

Touching on the complexity of landscape of Indian road conditions, Abijit Sengupta, Head of Business – SAE and India, HERE Technologies, spoke about vehicle safety trends such as connected vehicles, autonomous, shared services and electrification.

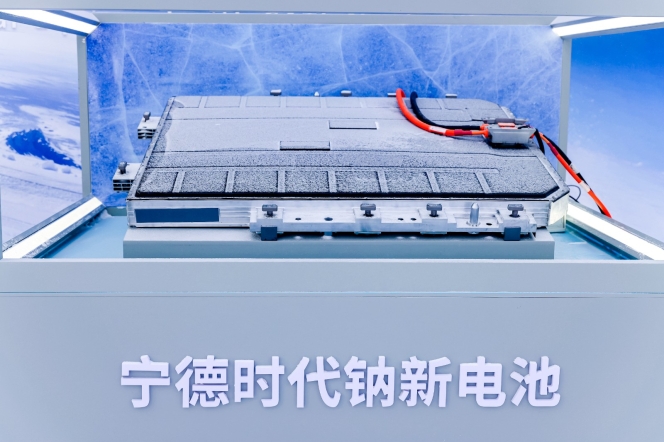

Changan And CATL Launch Mass-Production Sodium-Ion Battery Vehicle

- By MT Bureau

- February 19, 2026

Changan Automobile and CATL have unveiled the first mass-production passenger vehicle equipped with sodium-ion batteries. The vehicle, showcased at the 'Changan SDA Intelligence Milestone Release', is scheduled for market release by mid-2026. CATL, acting as the strategic partner for the project, will supply its Naxtra sodium-ion batteries across Changan’s brands, including Avatr, Deepal, Qiyuan and UNI. The partnership introduces a dual-chemistry approach to the market, utilising sodium-ion alongside lithium-ion technologies.

CATL's Naxtra battery reaches an energy density of 175 Wh/kg. Utilising a Cell-to-Pack system and a battery management system (BMS), the technology provides a range exceeding 400 km. Future iterations are projected to reach 500–600 km for battery electric vehicles (BEVs) and 300–400 km for hybrids.

The technology is designed for operation in cold climates. At –30deg Celsius, the battery delivers triple the discharge power of lithium iron phosphate (LFP) alternatives. It maintains 90 percent capacity retention at –40deg Celsius and continues to function at –50deg Celsius. Safety testing, including drilling and crushing, resulted in no smoke or fire.

The global sodium-ion battery market is forecast to grow from USD 1.39 billion in 2025 to USD 6.83 billion by 2034. To support adoption, CATL plans to establish over 3,000 Choco-Swap battery swap stations across 140 cities in China by the end of 2026, with a focus on northern regions.

The launch follows a decade of research. Since 2016, CATL has invested nearly 10 billion RMB (USD 1.45 billion) into sodium-ion technology, developing approximately 300,000 test cells. The project was supported by a dedicated team of 300 personnel to ensure scalability and performance.

Gao Huan, CTO of CATL's China E-car Business, said, "The arrival of sodium-ion technology marks the beginning of a dual-chemistry era. Changan's vision shows both its responsibility for energy security and its strategic foresight. Much as it embraced electric vehicles years ago, Changan is once again taking the lead with its sodium-ion roadmap. At CATL, we value the opportunity to work alongside such an industry leader and fully support its strategy, combining our expertise to bring safe, reliable and high-performance sodium-ion technology to market."

drivebuddyAI Demonstrates Scalable ADAS Platform At India’s First ADAS Test Track

- By MT Bureau

- February 18, 2026

Following its international unveiling at CES 2026, drivebuddyAI, a leading innovator in AI-powered Advanced Driver Assistance Systems (ADAS) and Driver Monitoring Systems (DMS), recently demonstrated its technology at the ARAI ADAS Test City. The company presented its range of vision-based Advanced Driver Assistance and Driver Monitoring Systems, focusing on their reliability in the varied and challenging conditions typical of Indian roads.

Live demonstrations were conducted using a heavy commercial vehicle to showcase the platform's versatility in meeting various compliance standards. A single, integrated hardware and software setup, utilising a fused network of cameras for 360-degree perception, executed multiple test scenarios simultaneously. These included a driver monitoring system that detects drowsiness, distraction and seatbelt usage in line with both Indian and European regulations. Further tests illustrated the vehicle's ability to warn of pedestrians moving into its path, identify potential collisions with cyclists in blind spots and issue forward collision warnings by combining radar and camera data.

Beyond merely fulfilling test requirements, the demonstrations highlighted practical applications that extend into everyday driving situations. This focus on real-world functionality is backed by extensive validation, with the company's systems having analysed nearly four billion kilometres of driving data. This has reportedly led to significant safety improvements, including a marked decrease in incidents caused by driver fatigue and a substantial reduction in overall fleet risks.

Currently validated for commercial vehicles against India's AIS-184 standard and Europe's stringent General Safety Regulation and Euro NCAP protocols for 2026, the technology is also adaptable for passenger cars. This scalability offers automotive manufacturers and their suppliers a pathway to not only meet but surpass upcoming global safety mandates. By refining its AI through extensive fleet operations over billions of kilometres before adapting it for original equipment manufacturer compliance, drivebuddyAI aims to deliver a mature, rigorously tested product that ensures an enhanced user experience.

Nisarg Pandya, CEO and Founder, drivebuddyAI, said, “ADAS Test City from ARAI is a great initiative, and we value participating in a format where we can showcase live demonstrations to a large audience together on the vehicle. This time, the turnout was significant and provided a strong opportunity to establish drivebuddyAI as one of the key players in the upcoming OEM compliance requirements. The engagement and response we received were phenomenal, reinforcing both the market need and the industry’s confidence in our solutions. The upcoming ADAS-compliant vehicles must have technology that works in Indian scenarios to achieve meaningful safety improvements and reduce fatalities.”

Comments (0)

ADD COMMENT