Henkel Adhesives Plant In India To Serve Emerging Markets

- By 0

- April 05, 2020

The phase I and II of the plant, set up investing INR 400 crore, will boost its capabilities to serve customers across sectors including flexible packaging, automotive, agriculture and construction equipment, general industry and metals. The plant which will cater to the local and export markets employs 300 people. The phase III and IV will be launched later at an estimated cost of INR 400 crore.

“India is one of the most important emerging markets with tremendous growth opportunities for our adhesives business,” Jan-Dirk Auris, Member of the Management Board and Executive Vice President, Adhesive Technologies business unit, Henkel AG & Co. KGaA, said. “We have application experts across manufacturing industries worldwide and work closely with our customers and partners. Our trusted brands and leading solutions based on our unmatched portfolio of 40 technologies create sustainable value for our customers. With the launch of this state-of-the-art, multi-technology manufacturing facility, we have created capacities to meet the demand for our high impact solutions in this dynamic market. This investment will enable us to further drive profitable growth,” he added.

Momentum in megatrends in the automotive sector will fuel demand for the company’s adhesive products, which help reduce vehicle’s weight. “Electric and connected vehicles need more adhesives than IC engine vehicles. We will continue to bring out products and solutions based on consumer demand and suitable for the new mobility, connectivity and sustainability,” Auris said.

The new plant is part of Henkel’s big bet on the emerging markets. Half of its total sales of USD 20 billion is from them. “India is the largest among the top 3 emerging markets. We believe tremendous demand will come from India for adhesives in the next decade. Henkel’s products are ‘invisible but essential’ and work as enablers for its consumers to improve efficiency and quality. Being a highly impactful solutions supplier, we also need to manage the risks,” he said.

Smart Factory

The Kurkumbh site is equipped with technologies to ensure traceability and transparency by ensuring built-in quality. End-to-end digitalisation of the plant operations has enabled digitised workflows; thus, making manufacturing more efficient. It deploys closed material handling systems and high level of process automation. For the first time, as a global pilot in Henkel, the site has implemented deep integration of process automation with Smart Factory (Industry 4.0).

The site meets the highest standards of sustainability. It is among the very few chemical manufacturing sites to be awarded the LEED Gold Certificate by the US Green Building Council based on a holistic energy efficiency concept. About 10 percent of its power consumption comes from captive solar energy and 16 percent of the annual water requirement is met by rainwater harvesting. Air and waste water discharges are monitored online.

Shilip Kumar, President, Henkel India, said, “We will continue to invest in local manufacturing as it gives our Adhesive Technologies business in India a strategic advantage. The Kurkumbh manufacturing site is a very important milestone of Henkel’s journey in India. This site will not only cater to the Indian market but also markets in the Middle East, Africa and South Asia. As market leaders in this industry, our focus is to offer high impact solutions to our customers and convert latent market potential into profitable growth.”

Henkel Adhesive Technologies is a global leader in adhesives, sealants and functional coatings. The business unit serves around 130,000 customers in over 800 industrial areas with tailor-made products and technologies used in a wide array of consumer goods and industrial products. (MT)

British Battery Tech Company EQONIC Group Strengthens Senior Leadership With New Appointments

- By MT Bureau

- February 12, 2026

EQONIC Group, a UK-based battery technology company, has announced two senior leadership appointments to support the commercialisation of its lithium-free, sodium-free and rare-earth-free battery technology.

John Saunders joins as Executive Director, bringing 30 years of experience in banking, regulation and law. He has held senior roles at Coutts, Barclays, UBS and Deutsche Bank. On the other hand, Angela Knight CBE joins as Non-Executive Director, having previously served as Chief Executive of the British Bankers' Association and Energy UK, with board experience at Taylor Wimpey and Arbuthnot Banking Group.

EQONIC is developing proprietary technology that eliminates the use of lithium, sodium, and rare-earth metals. The company claims that its technology achieves materials cost savings of approximately 70 percent compared to traditional lithium batteries.

The technology utilises abundant materials that are non-flammable, which reduces the risk of thermal runaway. This approach is intended to address supply chain vulnerabilities and ensure the batteries are fully recyclable.

The company plans to license its technology to Original Equipment Manufacturers (OEMs) to enable global deployment while reducing capital risk. EQONIC’s roadmap aims for its technology to surpass sodium battery performance by 2026 and reach Nickel Manganese Cobalt (NMC) levels by 2029.

Currently, EQONIC operates a commercial division serving D2B and B2B clients with lithium iron phosphate (LFP) energy storage systems. The company has secured a multi-million-pound pipeline across multiple sectors.

John Saunders, Executive Director, EQONIC Group, said, "EQONIC's breakthrough technology represents a genuine paradigm shift in the battery sector. The combination of cost reduction, enhanced safety, and sustainable materials addresses the fundamental barriers that have constrained the industry. I'm excited to bring my experience to support the company's growth trajectory as we move toward demonstrating market-ready products and securing strategic partnerships."

Angela Knight CBE, Non-Executive Director, EQONIC Group, said, "EQONIC exemplifies the kind of innovative British technology that can lead global markets. The company's approach - developing transformative technology first, then building robust commercial frameworks around it, is hugely compelling. Strong governance will be critical as EQONIC scales its business model and establishes partnerships with established OEM’s. I look forward to contributing to the board's strategic oversight during this pivotal phase."

Jas Kandola, Founder and CEO, EQONIC Group, stated, "John and Angela bring exactly the calibre of leadership we need at this critical juncture. John's regulatory expertise and commercial acumen will be invaluable as we navigate partnerships and licensing arrangements, while Angela's governance experience across complex, regulated industries will strengthen our board oversight. These appointments reflect our commitment to building a world-class organisation capable of delivering on the enormous potential of our technology."

Einride Appoints Former Nvidia Executive Gary Hicok To Board Of Directors

- By MT Bureau

- February 12, 2026

Einride AB, a technology company specialising in electric and autonomous freight, has appointed Gary Hicok to its Board of Directors. He joins the company following a 25-year career at Nvidia, where he held several leadership roles in autonomous technology and automotive hardware.

The appointment comes as Einride prepares for a public listing on the New York Stock Exchange through a business combination with Legato Merger Corp. III.

During his tenure at Nvidia, Hicok served as Senior Vice-President of the Mobile Business Unit and led Automotive Hardware and Systems. He oversaw the development of the Nvidia DRIVE platform and the Tegra processor, which are used in safety-critical automotive AI and in-vehicle computing.

His experience spans engineering and executive leadership within AI-driven markets and global organisations. At Einride, he will focus on scaling autonomous platforms and managing industry partnerships.

Einride operates in seven countries with more than 25 enterprise customers. The company reports approximately USD 65 million in expected annual recurring revenue (ARR) from signed contracts, with a potential long-term ARR exceeding USD 800 million through joint business plans.

The company has secured regulatory permits for autonomous vehicle operations in the United States and Europe. Its platform uses proprietary AI technology to manage electric and autonomous fleets, targeting the global road freight market.

Gary Hicok said, “Einride is solving an industry-scale problem the right way. Its platform approach unlocks partnerships, accelerates innovation, and makes electrified and autonomous freight real. I’ve watched many smart companies struggle with doing everything in house. It doesn’t scale or leverage the expertise of the industry, whereas Einride’s approach does. I believe its approach is built to win.”

Robert Falck, Founder and Executive Chairman, Einride, said, “Gary brings deep, hands-on experience scaling autonomous technology through critical partnerships across the automotive and technological ecosystem. Working alongside the Einride team, his perspective on building and scaling safety-critical platforms with industry partners will strengthen our ability to deploy autonomy globally. We’re pleased to welcome him to the Board.”

Roozbeh Charli, Chief Executive, Einride, added, “Gary's expertise and experience in building high-performing teams tackling the most advanced technology development will be instrumental for us as we continue to scale and cement our leadership position within autonomous freight technology. I’m incredibly proud of what we’ve built so far, and I’m excited for what we’ll achieve together with Gary’s unique experience.”

BorgWarner Secures 800V Integrated Drive Module Award for European REEV

- By MT Bureau

- February 12, 2026

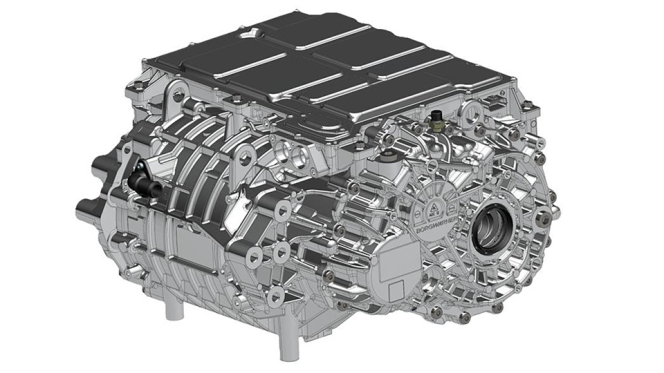

American powertrain major BorgWarner has been awarded a contract by a European original equipment manufacturer (OEM) to supply an 800V Integrated Drive Module (iDM). The system will support a Range Extended Electric Vehicle (REEV), with mass production scheduled to commence in 2029.

The iDM is a system incorporating a single-electric-machine design that provides both generator and drive functionality. The module operates alongside an inverter, two clutches and a dual-mass flywheel. It is paired with the customer's internal combustion engine.

The system includes energy-efficient generator functionality and an all-wheel-drive mode. By combining two REEV functions into one product, the module aims to optimise vehicle architecture.

The integrated inverter utilises Viper power switches and dual-side cooled power module technology. This platform is designed for high-performance electric drive applications to manage high-voltage and high-current requirements.

Dr. Stefan Demmerle, Vice-President, BorgWarner Inc. and President and General Manager, PowerDrive Systems, said, “Securing this program award underlines BorgWarner’s strength in electric drive technology and system integration. With the China team taking the lead and collaborating with a global team, we have created a highly integrated solution that balances performance, efficiency, and packaging. We are proud to support our customer with innovative technology for its next-generation range extended vehicles.”

BorgWarner maintains in-house capabilities across electric motors, drivelines, power electronics and software. The company intends to use its manufacturing footprint to support the development of the global energy vehicle market.

Aimtron Electronics Secures Initial European Order For Box-Build Solutions

- By MT Bureau

- February 11, 2026

Vadodara-based Electronics System Design and Manufacturing (ESDM) company Aimtron Electronics has secured its first order from a European Original Equipment Manufacturer (OEM). The contract, valued at approximately INR 38 million, involves providing box-build solutions for a client headquartered in Europe with manufacturing operations in Spain.

The order marks the company's entry into the European market, serving automotive and industrial sectors. Aimtron anticipates that revenues from this engagement could scale to four times the current size during the 2027 financial year.

The development follows the announcement of the India–Europe Free Trade Agreement (FTA), which aims to improve the competitiveness of Indian manufacturers. Aimtron intends to leverage its manufacturing operations in India and the United States to diversify supply chains for European customers.

This European foray follows the company’s recent acquisition of a US-based electronics system design and manufacturing (ESDM) firm to strengthen its engineering capabilities for global OEMs.

Sneh Shah, Whole-time Director, Aimtron Electronics, said, “Meeting European automotive requirements demands a high level of process discipline, quality governance, and execution consistency. Aimtron has invested steadily in building these capabilities across box-build, traceability, and program management. This engagement reflects that readiness and provides a clear pathway to scale programs across European end-markets.”

Comments (0)

ADD COMMENT