Hydrogen Fuel Cell Technology Takes Over The Industry

- By MT Bureau

- October 10, 2020

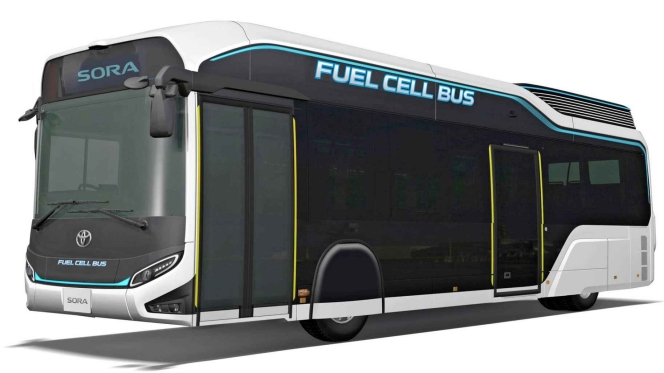

You must be wondering, what exactly is hydrogen fuel cell (HFC) technology, and what is so good about it? Hydrogen fuel is a clean fuel that is burned along with oxygen in an electrochemical power generator to generate electricity, and in the process, produces water and heat as by-products. What sets hydrogen fuel apart, however, is the fact that it serves as an alternative to diesel fuel in more ways than one: its fuel-cycle emits no pollutive exhaust, and through renewable energy, there contains no trace of greenhouse gas emissions. Vehicles that are powered by the hydrogen fuel cell, thus, significantly reduce our use and dependence on diesel oil and lower the chances of harmful emissions contributing to climate change. What started out as an experiment among startup companies and early projects is now dominating the commercial vehicle industry with many of the industry’s biggest players putting in large investments in the technology.

You must be wondering, what exactly is hydrogen fuel cell (HFC) technology, and what is so good about it? Hydrogen fuel is a clean fuel that is burned along with oxygen in an electrochemical power generator to generate electricity, and in the process, produces water and heat as by-products. What sets hydrogen fuel apart, however, is the fact that it serves as an alternative to diesel fuel in more ways than one: its fuel-cycle emits no pollutive exhaust, and through renewable energy, there contains no trace of greenhouse gas emissions. Vehicles that are powered by the hydrogen fuel cell, thus, significantly reduce our use and dependence on diesel oil and lower the chances of harmful emissions contributing to climate change. What started out as an experiment among startup companies and early projects is now dominating the commercial vehicle industry with many of the industry’s biggest players putting in large investments in the technology.

How Does it Work?

Hydrogen fuel can be produced through several methods, and in the commercial vehicle industry, fuel is processed in a fuel cell that is composed of three main components: an anode, a cathode, and an electrolyte membrane. This type of fuel cell is called a Proton-Exchange Membrane Fuel Cell, or also known as a polymer electrolyte membrane (PEM) fuel cell, which is mainly reserved for transport applications and stationary and portable fuel cell applications. The PEM fuel cell does its job by passing hydrogen through the anode, at which hydrogen molecules are split into electrons and protons. The former ones take the path of a circuit in the fuel cell to generate electric current and excess heat, while the protons go through the electrolyte membrane. At the same time, the PEM fuel cell passes oxygen from the surrounding air through the cathode on the other side, where the oxygen meets with the protons and electrons to produce water molecules. This does not get any simpler than your run-of-the-mill science experiment in school!

What Are Fuel Stacks Then?

What Are Fuel Stacks Then?

What lies in the heart of a fuel cell vehicle (FCV) is the fuel cell stack. Because fuel cells generate less than 1.16 volts of electricity each, they must be assembled atop one another to create a fuel cell stack in order to generate enough power to run a vehicle. The potential power that can be generated by a fuel cell stack largely varies and is dependent on the number and the size of the individual fuel cells of the fuel cell stack, as well as the surface area of the PEM.

The Preferred Alternative

Hydrogen fuel cell has been proven to yield positive results for both the environment and the wallet in the long term.

Reduction in Greenhouse Gas Emissions

Contrary to diesel fuel, which emits greenhouse gases (GHGs) and carbon dioxide (CO2) that are large contributors to climate change, the only by-products of vehicles–when fueled by pure hydrogen–are heat and water with the release of zero tailpipe GHGs. While it is possible for FCVs to still generate GHGs, depending on the production method, the GHGs emitted is still far less great than those emitted by gasoline and diesel fuel. FCVs also eliminate the maintenance costs that come with storing diesel fuel that may prove harmful later on. Many of the industry’s big players make use of environmentally benign hydrogen in their hydrogen fuel cell products to eliminate and prevent the harmful impact of fuel spillage or leaks and air pollution.

Cutback on Vehicle Oil Dependence

Cutback on Vehicle Oil Dependence

Many companies have incorporated hydrogen fuel cells in their corporate sustainability programmes, and the industry is seeing a shift of focus from diesel fuel to environmentally friendly alternatives. With the industry soon to be saturated with FCVs, our dependence on foreign oil will be significantly reduced and eventually eradicated. Hydrogen can be extracted sustainably from domestic sources, such as natural gas and coal, as well as from renewable sources, such as water, biogas, and agricultural waste. From an economic perspective, this would allow us to be less affected by oil price hikes and drops in the volatile oil market.

Lowering of Operational Costs

Hydrogen fuel cells require little to no maintenance as they eliminate the need to change, charge, and manage batteries, a maintenance check that is necessary for batteries, internal combustion generators, and the like. Hydrogen fuel cell units have a longer running time than do lead-acid batteries and, when power is running low, would not take more than five minutes to refuel. Companies that employ FCVs in their fleet benefit substantially from this as it reduces vehicle and personnel time, giving birth to a higher efficiency rate. This loss of regular maintenance saves not only money but labour, time, and the space for battery rooms as maintenance checks require optimal conditions.

Increase in Energy Efficiency

Increase in Energy Efficiency

Hydrogen fuel cells are well known to be more energy-efficient than other forms of power. When a fuel cell vehicle is fueled by pure hydrogen, the hydrogen fuel cell has the potential to be up to 80-percent efficient. This means that the fuel cell converts up to 80 percent of the energy content of the hydrogen into electrical energy. The electric motor and inverter of the vehicle thus have the responsibility to convert that electrical energy into mechanical energy, with an average of 80 percent efficiency. Combined, this gives an overall 64-percent of increased efficiency when a vehicle is powered by a hydrogen fuel cell!

Increase in Durability and Reliability

Hydrogen fuel cells are notably more robust than other forms of fuel and can weather all types of conditions, from cold environments to harsh storms. This makes fuel cells a reliable asset to companies that engage commercial vehicles in tough environments. Additionally, because they do not have any moving parts, hydrogen fuel cells operate quietly even in the midst of a snowstorm!

With environmentally friendly applications and time-consuming maintenance, we are beginning to see the boom of hydrogen fuel cell technology in the commercial vehicle industry, and with good reason! (MT)

(Credits / Sources: U.S Energy Information Administration, Hydrogenics, Toyota, Verdict Media, Stanford University, University of Nebraska, Fuel Economy, Plug Power)

ZF, BMW Sign Long-Term Supply Agreement For Drive Technologies

- By MT Bureau

- February 03, 2026

German tier 1 supplier ZF Friedrichshafen and the BMW Group have entered into a long-term supply agreement for passenger car drive systems. The contract, valued at several billion euros, extends until the late 2030s.

The agreement focuses on the supply and continued development of the 8-speed automatic transmission (8HP). The partners aim to support low-emission mobility and maintain technological flexibility during the industry transition.

A central component of the partnership is the technical evolution of the 8HP transmission kit to meet the requirements of electrified drives. The development will focus on increasing efficiency and performance for future vehicle concepts.

Mathias Miedreich, CEO of ZF, said, “Together with BMW, we are sending a strong signal for innovation, efficiency, and sustainability in an industry undergoing dynamic change. This agreement highlights the strategic importance of our 8-speed automatic transmission as a key technology for the transformation of drive systems.”

The duration of the contract provides both ZF and BMW with planning stability in a changing market. ZF aims to strengthen its position as a system supplier while reducing risks through close collaboration with the carmaker.

Sebastian Schmitt, Head of ZF's Electrified Drive Technologies division, explained, “The new agreement with BMW shows how important long-term planning horizons are for technological advancements. It creates clarity and stability for both companies and enables us to align the next generation of the 8HP specifically toward efficiency, performance, and long-term viability.”

Leapmotor Selects Aumovio For Safety Technologies

- By MT Bureau

- February 02, 2026

Aumovio has entered a supply agreement with Chinese electric vehicle manufacturer Leapmotor to provide safety components for the carmaker’s B and C platforms.

Several models within Leapmotor’s B platform now utilise Aumovio's long-range radar, electric parking brake and airbag control unit (ACU). Models on the C platform, including the C10, C11 and C16 SUVs, feature the latest generation of the MK C2 one-box brake system, alongside the long-range radar and ACU.

The project was completed with a development cycle approximately one-third shorter than traditional automotive timelines. Aumovio attributed its speed to ‘local-for-local’ strategy in China, where the company operates 20 sites and employs around 10,000 staff. In 2024, Aumovio held a 14 percent share of market revenue in the region.

The supplied technologies include:

- MK C2 Brake System: A unit combining the master cylinder, electronic brake system, and brake booster. It is produced locally in Shanghai.

- Long-Range Radar: A sensor with a detection range of up to 280 metres, used for driver assistance across both platforms.

- Airbag Control Unit (ACU): Integrated with crash satellite sensors, these components are manufactured in Changchun.

Boris Mergell, Head of the Safety and Motion business area at Aumovio, said, “Pairing ‘China speed’ with ‘German quality’ technologies helped us to support a rapid roll-out with our latest safety technologies. This underscores Aumovio’s course towards an adaptive powerhouse that works flexibly and closely with customers to innovate. It also shows that we continue to strengthen our customer relationships in the important market China.”

The partnership supports Leapmotor’s international presence. The B10 and B05 models, which feature Aumovio's ACU and radar technology, were showcased at the IAA 2025 in Munich as part of the manufacturer's European entry.

LTTS Secures Multi-Year Deal From Automotive OEM For Engineering And R&D

- By MT Bureau

- January 28, 2026

Bengaluru-headquartered ER&D company L&T Technology Services (LTTS) has announced a multi-year engagement within its mobility segment from an automotive manufacturer. The agreement involves software, connectivity and digital engineering services across vehicle technology domains. This win follows the company’s investments in R&D labs and mobility infrastructure designed for programs with global manufacturers.

The engagement covers mobility engineering capabilities, including embedded systems, digital platforms, verification and validation, cloud integration and cybersecurity. LTTS intends to use its engineering expertise and delivery frameworks to support the customer's technology roadmap.

At present, LTTS operates 22 design centres and 100 innovation labs globally.

The agreement strengthens the partnership between LTTS and the automotive manufacturer in the area of mobility engineering. The company provides design, development, and testing services across the mobility, sustainability, and tech segments.

Alind Saxena, Executive Director and President, Mobility and Tech at L&T Technology Services, said, “We are proud to deepen our partnership with the valued customer through this strategic engagement. LTTS brings together domain-led engineering, secure development practices and excellence in global delivery to accelerate the future of premium mobility. The win reflects the trust placed in our teams and our commitment to delivering world-class engineering at scale”.

Valeo And NATIX Network Partner To Develop Open-Source World Foundation Model

- By MT Bureau

- January 25, 2026

French technology company Valeo and NATIX Network have announced a partnership to develop a multi-camera World Foundation Model (WFM). The project combines Valeo’s research in artificial intelligence and generative modelling with NATIX’s decentralised physical infrastructure network (DePIN) to create an open-source platform for autonomous driving and robotics.

The initiative aims to move beyond perception-based models by creating a system capable of predicting future states and reasoning about physical interactions in a four-dimensional environment. The model will be trained using NATIX’s data network, which has collected 600,000 hours of video data across the US, Europe and Asia over seven months. This data provides the multi-camera inputs necessary for the spatial perception required by autonomous vehicles and robots.

The partnership builds upon Valeo’s existing open-source frameworks, VaViM (Video Autoregressive Model) and VaVAM (Video-Action Model). While these frameworks were previously trained primarily on front-camera datasets, the integration of NATIX’s multi-camera network expands the AI’s field of vision to 360 degrees.

Under the open-source framework, the partners will release models, datasets and training tools. This approach is intended to allow the research community to fine-tune models and benchmark physical AI across various driving conditions and geographic regions. The collaboration seeks to accelerate the deployment of end-to-end AI models by learning from real-world edge cases captured by vehicles in operation.

Marc Vrecko, Chief Executive Officer, Valeo’s Brain Division, said, “Since our creation in 2018, Valeo’s AI research center has been at the forefront of AI research in the automotive industry, especially in the fields of assisted and autonomous driving. Our goal has always been to advance mobility intelligence safely and responsibly. By combining Valeo’s generative world modeling research expertise with NATIX’s global multi-camera data, we are accelerating both the quality and the accessibility of next-generation end-to-end AI models, enabling the research community to build upon strong open models.”

Alireza Ghods, CEO and Co-Founder, NATIX, added, “WFMs are a once-in-a-generation opportunity — similar to the rise of LLMs in 2017–2020. The teams that build the first scalable world models will define the foundation of the next AI wave: Physical AIs. With our distributed multi-camera network, NATIX has a clear advantage of being able to move faster than large OEMs.”

Comments (0)

ADD COMMENT