ACMA’s 3rd Automotive Raw Materials Conclave And Exhibition

- By MT Bureau

- August 04, 2023

The Automotive Component Manufacturers Association of India (ACMA) in partnership with the Alloy Steel Producers Association (ASPA) conducted the 3rd Automotive Raw Materials Conclave and Exhibition in Delhi recently. Held under the theme ‘New Age Materials - Challenges And Opportunities’, the conclave brought together key stakeholders to discuss the transformative potential of advanced materials in the automotive industry.

Providing insights on how efficiencies can be brough in and how sustainability and circularity could be deployed in case of next-generation materials, the event focused on cutting-edge materials in context with vehicle design, safety and sustainability. It also focused on challenges such as commodity price fluctuations, geo-political instability and geographic material concentration in terms of the transition from traditional raw materials to the new age materials. While a PwC Report presented at the conclave stressed on the above factors, the conference saw experts and industry leaders speak about the convergence of multiple factors like improved vehicle performance and enhanced safety standards in terms of new material choices in components for automotive applications.

Gopalakrishnan Ganesan, Deputy Secretary, Ministry of Steel, Government of India, said, “We've witnessed remarkable progress in the automotive and steel industries over two decades, complementing each other and aligning with government goals. The PLI Scheme for Steel has been a driving force, especially for alloy steel in fostering innovation. The Government, the Steel Industry and the Automotive industry, together need to forge a self-reliant innovative future, creating ground-breaking products in advancing the nation.”

Vinnie Mehta, Director General, ACMA, expressed, “In this era of rapid technological evolution and environmental consciousness, the automotive sector finds itself at a critical juncture. The convergence of electrification, autonomous driving, and the pressing need for eco-friendly transportation necessitates a radical rethinking of raw materials.” “At ACMA, we firmly believe that challenges are opportunities in disguise. The complexities that lie ahead, from securing a stable supply of critical minerals to scaling up the production of new-age materials, present us with opportunities to innovate, collaborate, and create lasting impact. This conclave provides us with an ideal platform to forge partnerships, share knowledge, and collectively shape a sustainable roadmap for the industry,” he added.

The key themes explored during the 3rd Automotive Raw Materials Conclave and Exhibition were,

Advancements in lightweight materials and their impact on fuel efficiency and environmental sustainability.

High tensile strength alloys and their contributions to vehicle safety and performance.

Sustainable manufacturing practices and their role in reducing the automotive industry's ecological footprint.

Emerging trends and innovations in automotive materials, presenting opportunities for growth and competitiveness.

Sunil Kakkar, Senior Executive Director, Maruti Suzuki India Ltd., and the chief guest of the event averred, “In the rapidly transforming automotive industry, we see significant challenges and opportunities. The regulatory environment in India is aligning with global norms, and trends like connected, autonomous, shared, and electric mobility are shaping the industry’s future. Despite the pandemic, the industry has shown resilience, and our unsaturated market offers vast growth potential. Collaboration between steelmakers and the automotive industry is crucial to meet the safety, emission, and light-weighting needs of the industry. We are committed to a greener, safer, and more innovative future, embracing ESG measures for a sustainable ecosystem.”

Several alloy steel manufacturers also displayed their next-generation products at the event.

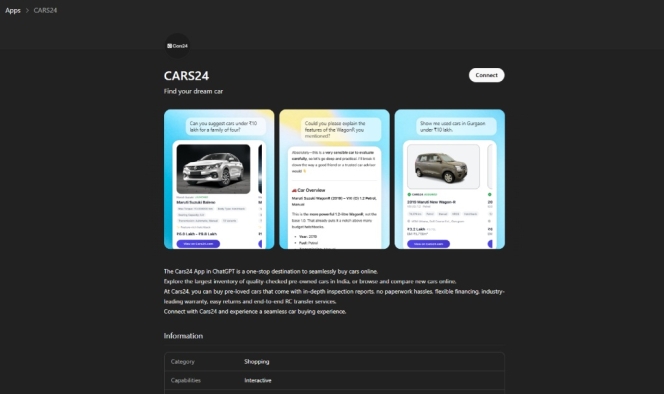

Cars24 And OpenAI Partner To Integrate AI into Automotive Commerce

- By MT Bureau

- March 02, 2026

Cars24 has announced a strategic partnership with OpenAI to deploy artificial intelligence (AI) models and agents across its business operations. The collaboration focuses on embedding AI into vehicle discovery, sales, financing and post-purchase engagement across all markets where the company operates.

Unlike traditional pilot programmes, the initiative involves the integration of OpenAI’s technology into production environments to manage high-volume workflows. The partnership aims to transition the platform from manual automation to systems that assist in decision-making and data retrieval.

Cars24 has already deployed OpenAI’s Enterprise APIs across several internal and customer-facing functions. According to company data, the integration has resulted in a 50 percent increase in support resolution through assisted troubleshooting and an 80 percent reduction in turnaround time for service workflows.

Current deployment statistics include:

- Customer Outreach: AI agents now manage 20 percent of outbound conversations.

- Internal Adoption: 85 percent daily active usage of ChatGPT Enterprise among the central workforce.

- Functionality: Teams utilise the tools for data analysis, code development, and the summarisation of operational cases.

- Accessibility: The Cars24 application is now available on the ChatGPT Store for conversational vehicle discovery.

The partnership is designed to reduce dependencies on manual processes in automotive transactions. By embedding models into core workflows, the company intends to shorten decision cycles for buyers and sellers. Future phases of the rollout will include expanding these AI experiences to additional languages and product lines.

Vikram Chopra, CEO and Founder, Cars24, said, “Automotive commerce is operationally heavy by nature with multiple checkpoints, fragmented information and high-consideration decisions. Over time, we’ve realised that incremental improvements aren’t enough; the system itself needs to become more intelligent. Our collaboration with OpenAI is a step in that direction. By embedding AI into core workflows rather than layering it on top, we can reduce manual dependencies, improve consistency and shorten decision cycles. We don’t see this as a short-term advantage, but as foundational infrastructure that will compound in efficiency and trust over the years.”

- Tata Technologies

- WITTENSTEIN High Integrity Systems

- WHIS

- Andrew Longhurst

- Software Defined Vehicle

- SDV

- Nachiket Paranjpe

Tata Technologies Partners WHIS To Advance SDV Development

- By MT Bureau

- March 02, 2026

Tata Technologies has announced a partnership with WITTENSTEIN High Integrity Systems (WHIS) to accelerate the development of Software-Defined Vehicles (SDVs). The collaboration involves integrating WHIS’s SAFE RTOS into Tata Technologies’ automotive software stack.

The integration is designed to assist original equipment manufacturers (OEMs) and Tier 1 suppliers in meeting functional safety standards, such as ISO 26262. The partnership focuses on the transition towards connected, autonomous, and electrified mobility by providing safety-certified architectures for complex vehicle ecosystems.

SAFE RTOS provides real-time performance and reliability, serving as a component within the Tata Technologies SDV platform. This allows for the development of software architectures that support the increasing centrality of software in vehicle design.

The partnership combines Tata Technologies' experience in automotive software with WHIS's embedded software solutions to address requirements for scalable and certified systems.

Andrew Longhurst, Managing Director, WITTENSTEIN High Integrity Systems, said, “Software is at the heart of the automotive industry’s evolution. Our partnership with Tata Technologies ensures that OEMs and Tier 1 suppliers can leverage SAFE RTOS to achieve the highest levels of safety and performance in their software-defined vehicle architectures.”

Nachiket Paranjpe, President – Automotive Sales, Tata Technologies, added, “By combining Tata Technologies’ expertise in automotive software development with WHIS’s proven safety solutions, we are empowering our customers to accelerate SDV adoption and deliver cutting-edge mobility experiences.”

CATL And BMW Sign Agreement On Battery Passport And Decarbonisation

- By MT Bureau

- March 01, 2026

CATL and the BMW Group have signed a Memorandum of Understanding (MoU) to expand cooperation on battery supply chain data exchange and decarbonisation. The agreement was finalised in Beijing during a visit by a German delegation including Chancellor Friedrich Merz.

The partnership focuses on pilot projects for cross-border data transfer under the Battery Passport framework. The companies will collaborate on carbon accounting methodologies and tools to calculate the carbon footprints of power batteries.

The initiative utilises Catena-X, a standardised automotive data ecosystem, to align technical standards and policy frameworks. By testing Battery Passport applications, CATL and BMW aim to meet China-EU regulatory requirements and establish global data standards for the battery industry.

The cooperation is intended to improve digital management and ensure compliance with EU market access regulations regarding green product competitiveness.

The strategic relationship between CATL and BMW began in 2012. Previous collaborations have covered battery production, research and development and supply chain sustainability. This MoU shifts the partnership from product-level cooperation to institutional coordination for electric mobility.

CATL stated its intention to continue cooperation with international partners to use technology for the global energy transition and the sustainability of the automotive sector.

BMW Group bringing Physical AI And Humanoid Robots To Europe

- By MT Bureau

- February 28, 2026

The BMW Group is accelerating the digital transformation of its manufacturing operations by embedding artificial intelligence deeply into physical processes. A central focus of this strategy is Physical AI, a concept that unites digital intelligence with machinery and robotics. This integration allows systems like humanoid robots to function effectively within live production environments. For the first time, this approach is being introduced in Europe through a pilot project at the company’s Leipzig plant, where humanoid robots will be tested in the assembly of high-voltage batteries and component manufacturing. This initiative builds on a previous deployment at the Spartanburg plant in United States, where valuable experience was gained and is now being used to refine and scale the technology.

Artificial intelligence is already embedded throughout the BMW production system, underpinning functions such as digital twins, AI-supported quality assurance and autonomous transport in intralogistics. A unified data architecture serves as the foundation for this intelligence, enabling real-time access to consistent and standardised information across all manufacturing locations. This infrastructure supports the deployment of digital AI agents capable of autonomous decision-making in complex environments. When these agents are paired with robotic systems, they give rise to Physical AI, which represents a significant evolution in production technology.

The company views humanoid robotics as a strategic addition to its automation portfolio. These robots are particularly suited to tasks that are repetitive, physically strenuous or present safety risks. By deploying them in such roles, the company aims to reduce physical strain on employees and enhance workplace conditions. To drive this forward, a Center of Competence for Physical AI in Production has been established to consolidate expertise and facilitate knowledge sharing across the organisation.

A structured process governs the evaluation of potential technology partners. Candidates are assessed against criteria related to maturity and industrial applicability, followed by laboratory testing using real production scenarios. Successful tests lead to limited deployments under actual factory conditions before advancing to full pilot phases. This methodology ensures that only thoroughly vetted solutions are integrated into series production.

The Leipzig pilot is being conducted in collaboration with Hexagon, a longstanding partner specialising in sensor technology and software. Following theoretical and laboratory evaluations, an initial deployment of Hexagon’s humanoid robot, AEON, took place at the plant in December 2025. A second test phase is scheduled for April 2026, with the full pilot set to begin in the summer of that year. The robot’s human-like design allows for the attachment of various tools and grippers, making it adaptable for multiple tasks in battery assembly and parts manufacturing.

Earlier work at the Spartanburg plant provided critical insights into the practical application of humanoid robotics. In partnership with Figure AI, the robot Figure 02 was deployed in body shop operations, where it handled the precise placement of sheet metal parts for welding. Over 10 months, the robot supported the production of more than 30,000 vehicles, operating in 10-hour shifts and handling over 90,000 components. The pilot demonstrated that humanoid robots could perform high-precision tasks reliably and safely in a live production setting. It also highlighted the importance of early collaboration with teams responsible for IT infrastructure, safety and logistics. Seamless integration into the existing automation ecosystem was achieved through standardised interfaces, and employee reception was notably positive, aided by transparent communication from the outset.

The success of these initial deployments has paved the way for further collaboration. BMW and Figure are currently exploring additional applications for the next-generation Figure 03 robot, continuing to build on the foundation established in both United States and Europe.

Milan Nedeljković, Member of the Board of Management of BMW AG, Production, said, “Digitalisation improves the competitiveness of our production – here in Europe and worldwide. The symbiosis of engineering expertise and artificial intelligence opens up entirely new possibilities in production,”.

Michael Nikolaides, Senior Vice President Production Network, Supply Chain Management at BMW Group, said, “Our aim is to be a technology leader and to integrate new technologies into production at an early stage. Pilot projects help us to test and further develop the use of Physical AI – that is, AI‑enabled robots capable of learning – under real-world industrial conditions. The successful first deployment of humanoid robots at our BMW Group plant in Spartanburg in the USA proves that a humanoid robot can function not only under controlled laboratory conditions but also in an existing automotive manufacturing environment.”

Michael Ströbel, Head of Process Management and Digitalisation, Order to Delivery at BMW Group, said, “We are delighted to deploy a humanoid robot for the first time in a pilot project at a plant in Germany. Following evaluation by our Center of Competence for Physical AI in Production, tests were carried out in the laboratory and at Plant Leipzig at the end of last year. This year, our focus is on step‑by‑step integration into our production system to explore a wide range of applications. The emphasis is on researching multifunctional use of the robot in various production areas such as battery manufacturing for energy modules and component production for exterior parts. With Hexagon, we have found a proven long‑standing partner with a highly innovative approach to humanoid robotics for this project.”

Felix Haeckel, Team Lead CoC Physical AI for Production, said, “At our new Center of Competence for Physical AI in Production, we are pooling our expertise to make knowledge on AI and robotics widely usable within the company. In recent years, we have built up an international team of experts that, in addition to in‑house research and programming, is dedicated to the gradual integration of AI into the existing production system. At the same time, our team in Munich is driving its own robotics research to set up, support and further develop pilot projects in the field of Physical AI at our plants.”

Arnaud Robert, President of Hexagon Robotics, said, “We are very pleased to be working with the BMW Group to advance the use of humanoid robots in real‑world environments.”

Comments (0)

ADD COMMENT