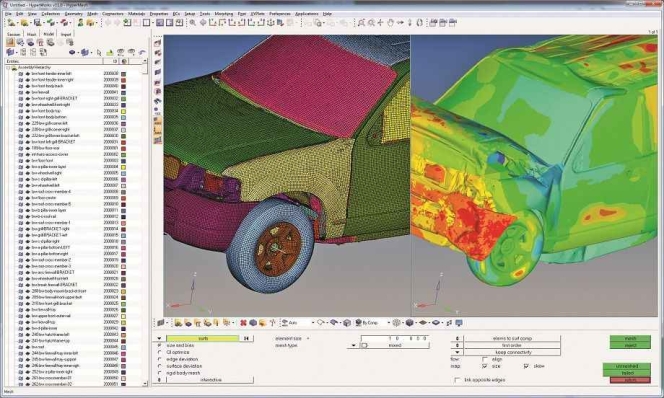

Altair Announces Software Updates For All Its Products

- By 0

- June 09, 2020

Altair today announced the most significant software update release in the company’s history. All of Altair’s software products have been updated with advancements in user experience and countless new features, including intuitive workflows that empower users to streamline product development, allowing customers to get to market faster.

The software update release expands on the number of solutions available for designers, engineers, data analysts, IT and HPC professionals, facility managers, and more to drive better decisions and accelerate the pace of innovation. It broadens the scope of the new user experience, enables access to more physics, data analytics, and machine learning, and makes the Altair software delivery method more flexible and accessible.

“Our teams are always driven to develop and provide access to a range of different technologies that enable our customers to break through complex problems, and explore and discover on their own terms. This software update release is the largest collection of our applications for design, simulation, and data analytics,” said James Scapa, Chairman, Founder and chief executive officer of Altair.

Some of the most notable highlights enhance and bring new capabilities to the needs aligned to the following applications:

· Structures

o Altair HyperWorks™ – new interface to Altair’s solution for high-fidelity computer-aided engineering (CAE) modeling and visualization, making learning easy and productivity high

o New subsystem entity for modular model configuration

o Altair SimLab™ – fatigue optimization

o Altair OptiStruct™ – includes the addition of new explicit solution and expanded implicit non-linear solutions including 2D axisymmetry

o Altair SimSolid™ – includes advanced 3D seam weld connections to further improve speed

o Altair Radioss™ – employs a dramatic reduction in runtimes for virtual drop testing of electronics devices

· Fluids and Thermal

o HyperWorks CFD – provides engineers and experienced computational fluid dynamics (CFD) specialists with the most productive CFD pre- and post-processing capabilities to-date

o Altair AcuSolve™ – GPU acceleration yields 3-4 times increased speed while also supporting nucleate boiling, radiation, condensation/evaporation and multiphase fluid-structure interaction (FSI)

o Altair ultraFluidX™ – includes a new, more accurate wall model and overset grid technique

o Altair nanoFluidX™ – is three times faster than the previous version

· Industrial Design and Structures

o Altair Inspire™ integration of Altair SimSolid™ solver includes support and connector reaction forces, instantaneous reaction time modeling large PolyNURBS models, and improved geometry generation from optimization

o Inspire Studio – advanced morphing of any geometry type

· Manufacturing

o 3D printing simulation available in Inspire with new unit cell lattice generation

· Electromagnetics and Multiphysics

o SimLab – electric motor modeling and coupling with AcuSolve and Altair Flux™; accommodates ECAD file import (ODB++)

o Altair Feko™ – provides a component library tightly integrated with CADFEKO

o Altair FluxMotor™ now includes thermal and acoustics evaluation

o Flux includes several enhancements including those for modeling iron losses and skew type motors

· Systems Modeling

o Altair Activate™ – performs multi-physics system modeling with hardware-in-the-loop and Internet of Things (IoT) for digital twin development

o Integration of EDEM bulk material modeling with multibody dynamics simulation and hydraulics ideal for heavy equipment and agricultural applications

o Altair MotionView™ – has a two-wheeler vehicle dynamics library for motorcycles and scooters

o Altair Compose™ – OpenMatrix Language available in Jupyter Notebook

o Altair Embed™ – supports three additional target and two additional target families from ST Micro, VRTOS code modifications for MISRA compliance, and OpenCV DNN (Deep Neural Network) module integration

· Data Analytics

o Recent release of Altair Panopticon™ – platform for user-driven monitoring of real-time data – includes major update of cloud-based deployment, enabling users to build, modify, and share custom-designed functions and content easily via standard web browsers; hotfix to enable deployment at Nomura

o Altair Knowledge Hub™ – improved messages for troubleshooting and robustness; security hardening; more flexible Windows deployment; deployment on Azure; transformations including continuous binning and lookup join (refactoring for performance) and more

o Altair Monarch™ – complex Excel input support – "Excel Trapping"; PDF extraction improvements; user experience and UI improvements; enhanced column list and more

o Altair Knowledge Studio™ – new features including Keras model, model stacking, and pivot table; variable transformations node improvements with dataset and variable preview and re-ordering

· Smart Product Development

o Altair SmartWorks™ – major re-architecture of the edge orchestration and augmentation; ability to validate the edge application in real-time environments and deploy at scale

· HPC and Cloud

o Altair Access™ – updated “work from home” features; more responsive 3D remote visualization; internationalization; better job resource charts; two-factor authentication and single sign-on; share support on mobile

o Altair Accelerator™ – EDA workload support on AWS (with Rapid Scaling), Microsoft Azure, and GCP; 10x faster for dynamic workloads; container improvements; REST query API; IPv6

o Altair PBS Professional® – scalability improvements towards exascale; Cray Shasta support; container enhancements for converged AI+HPC workloads; better system maintenance support. (MT)

Ola Electric To Unveil India Inside Vision On 15th August

- By MT Bureau

- August 06, 2025

Bengaluru-based electric vehicle maker Ola Electric is set to host its annual event ‘Sankalp’ on 15 August, at its Gigafactory in Krishnagiri, Tamil Nadu.

At the event, the company shared that it will unveil its ‘India Inside’ vision across products and technologies. This year, Ola Electric has made its event public inside the Gigafactory, which will be live-streamed on its official channels with more details to be announced soon.

Force Motors Launches AI-powered Connected Vehicle Platform, Sets Up Command Centre In Pune

- By MT Bureau

- August 05, 2025

Pune-headquartered automotive major Force Motors has unveiled Force iPulse, its new connected vehicle platform designed to enhance operational intelligence and vehicle lifecycle management.

Developed in partnership with Intangles, the platform uses state-of-the-art artificial intelligence (AI) and hybrid analytics to provide insight into vehicle performance. It continuously analyses high-resolution data to predict issues, enabling the early detection of performance problems and component failures.

Unlike traditional monitoring systems, Force iPulse goes beyond simply reporting faults. It performs root-cause analysis on key subsystems, including the engine, powertrain and electrical and thermal systems, allowing for proactive intervention to prevent unplanned downtime. This enables fleet operators to make precise, data-backed decisions.

Prasan Firodia, Managing Director, Force Motors, said, “At Force Motors, we believe in value-driven innovation, and this launch is yet another step in our mission to deliver superior, intelligent mobility solutions. Force iPulse is more than just a technological solution—it is a business enabler for our customers. It brings in transparency, improves efficiency, and ensures safety across operations, thereby equipping our customers with complete control over their fleet operations. We are confident that this new initiative will be well appreciated by both our customers as well as our partners and help take us another step forward in delivering our promise of customer delight.”

The platform, built on a secure cloud-native architecture, provides access to real-time and historical vehicle data on both mobile and desktop devices. It offers a unified view of operations, helping fleet managers detect inefficiencies, enforce best practices and optimise the total cost of ownership.

Furthermore, to support the new technology, Force Motors has established an Intelligence Command Centre at its headquarters in Pune. Manned by diagnostics experts, the centre provides remote vehicle monitoring, alert management and expert guidance. This is backed by a 24x7 support infrastructure.

Force iPulse is now available across Force Motors’ network of more than 300 dealerships. It will be a standard feature on all new commercial vehicles and can also be fitted as a certified aftermarket solution.

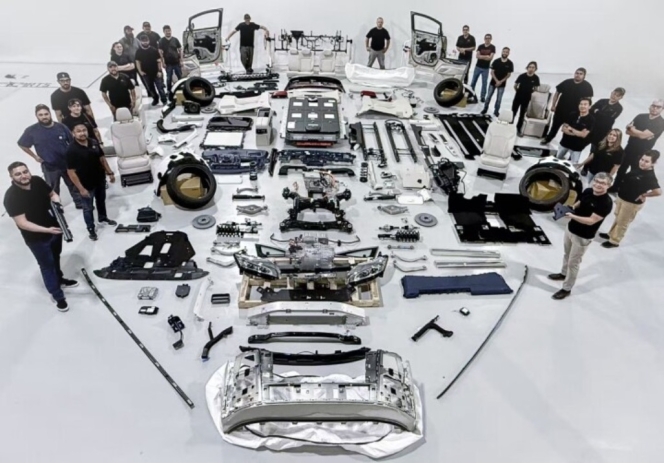

Faraday Future Begins Trial Production Of FX Super One MPV In California

- By MT Bureau

- August 04, 2025

California-based e-mobility company Faraday Future Intelligent Electric has commenced the trial production phase of its new FX Super One electric MPV at its Hanford facility.

The phase will focus on validating production processes, workflows and quality standards. Factory engineers and staff are also undergoing training to prepare for full-scale production. The next stage will involve engineering validation, including safety testing.

Unveiled in Los Angeles on 17 July, the FX Super One features Faraday Future’s Super EAI F.A.C.E. interface and its 6x4 Embodied AI Agent architecture. The model is positioned as a premium alternative to traditional large SUVs like the Cadillac Escalade.

The company has invested around USD 300 million in its 1.1 million-square-foot Hanford facility, which could be scaled up to produce over 30,000 vehicles per year with further funding and permits. The plant may also support multi-model assembly lines.

Faraday Future recently secured USD 105 million in new funding, expected to cover most of the FX Super One’s launch costs.

Founded in 2014, the company aims to disrupt the automotive industry by creating a user-centric, technology-first and smart driving experience.

Schaeffler Introduces Radar-Based Hands-Free Vehicle Access Sensor

- By MT Bureau

- August 04, 2025

German tier 1 supplier Schaeffler has developed a hands-free access sensor that allows users to open and close vehicle trunks or sliding doors with a foot motion, without needing to press a button or use a remote. Based on Doppler radar technology, the system enables keyless and contactless vehicle access.

According to Matthias Zink, CEO Powertrain & Chassis, Schaeffler AG, “With the expanded portfolio of the Powertrain & Chassis Division, Schaeffler is positioning itself as a new provider of innovative sensor solutions for body applications. The hands-free access sensor is an example of Schaeffler’s growing, complementary product range following the merger with Vitesco Technologies – and marks another step toward our goal of becoming the world’s leading Motion Technology Company.”

The sensor activates when a person enters the radar field beneath the rear of the vehicle. It detects foot movements and analyses both speed and direction within a 60-centimetre range. Artificial intelligence is used in the calibration process, adapting the system to different vehicle models to improve detection accuracy and reduce false triggers.

Production of the sensor began in Europe at the end of 2024 for major automotive manufacturers.

Leif Reinhold, Head of the Powertrain Solutions Business Division at Schaeffler, responsible for the company’s sensor portfolio, said. “Schaeffler’s hands-free access sensor is a key component in the vehicle for intuitive access and also highlights our expanded sensor expertise in the market. We have been producing the hands-free access sensor in volume since the end of 2024 – in Europe, for major European automotive manufacturers. We also see additional growth potential in North America and China.”

Operating at a 24 GHz frequency, the sensor maintains performance in various weather conditions and temperatures ranging from –40 to 105 degrees Celsius. It connects to vehicle systems via a LIN interface and is suitable for various body styles including SUVs, minivans and sedans.

The sensor can be mounted either on the bumper or the chassis and is compatible with vehicles fitted with or without a trailer hitch. Installation involves a single screw-in component, removing the need for extra clips, brackets or antenna runs.

Comments (0)

ADD COMMENT