Regenerative Production Of Hydrogen, Infrastructure Establishment- Key For Fuel Cell Growth

- By 0

- June 16, 2020

The first step towards whole vehicle development was the Project Mercury collaboration between Hyundai and United Technologies Corporation (UTC). A number of vehicles were developed during the collaboration, with system improvements in powertrain performance and increasing range capabilities culminating in the final vehicle, MercuryⅡ. This was based on the JM Tucson platform with an 80kW fuel cell system, 337km range and the ability to start from temperatures as low as -20 degree Celsius.

In 2000, Hyundai also launched the Polaris project in conjunction with the Korean Government’s G7 Project. The G7 Project was an initiative to help close the technological gap that existed between Korea and other advanced countries, specifically in the field of eco-innovation. The Polaris project saw Hyundai independently develop complete fuel cell vehicle systems, which lead to several project vehicles such as Polaris Ⅱ which showcased a Hyundai fuel cell system with an output of 80kW and a range of 370km.

At the same time as the PolarisⅡ was in development, Hyundai produced its first fuel cell bus in 2005, with a 160kW fuel cell system and an operating range of 380km. Hyundai also began in-house electric vehicle research in the early 1990’s. The two technologies became unified for the first time in the 2007 Tucson FCEV, which had a combined fuel cell and battery electric drivetrain output of 100kW and a range of 370km. Fuel cell bus development continued alongside passenger vehicles, with the 2009 2nd Generation Fuel Cell Bus offering a combined fuel cell system power of 200kW and an operating range of 380km.

2010 saw two milestones in the company’s fuel cell technology development: the accumulative distance covered by all Hyundai fuel cell vehicles reached the two million km mark and the new ix35 FCEV prototype was launched. This fuel cell vehicle was the first Hyundai to use high pressure 700bar fuel storage, boosting range to 635km from the 100kW fuel cell drivetrain.

Significantly in 2013, Hyundai became the first manufacturer to series produce the ix35 Fuel Cell electric vehicle. The 100kW fuel cell system and 700bar storage produced an NEDC certified 594km range.

In 2014, Hyundai unveiled the Intrado concept at the Geneva Motor Show. This concept showcased a focus on usability and adaptability, using advanced materials such as high strength steel and carbon fibre and new manufacturing and joining techniques that together have the potential to change the way cars are made. Intrado demonstrated a next-generation hydrogen fuel-cell powertrain with a hybrid Li-ion 36 kW battery, with a range of over 600 km.

By 2015, ix35 Fuel Cell sales were taking place across the world, including 13 countries in Europe. In the UK, 17 customers (from private companies, car sharing organisations and government agencies) became the first to drive hydrogen fuel cell cars. Across the European continent, the ix35 Fuel Cell vehicles on the road covered more than 1.2 million km’s.

Hyundai’s ongoing commitment to fuel cell development was shown in 2017, with the FE Fuel Cell concept that was shown at the Geneva Motor Show. It featured new drivetrain technology including a fuel cell stack 20 percent lighter than that of the ix35 Fuel Cell, yet with an increased power density of 30 percent and a range of over 800km.

2018 was another landmark year for the company’s fuel cell story, with the launch of NEXO, the only fuel cell SUV in the world. Following this the company announced its long-term roadmap - ‘Fuel Cell Vision 2030’ - to reaffirm its commitment to accelerate the development of a hydrogen society by leveraging the group’s global leadership in fuel-cell technologies. Aligned with the roadmap, Hyundai Motor Group has pledged to drastically boost annual fuel-cell system production capacity to 700,000 units by 2030 and explore new business opportunities to supply fuel-cell systems to other transportation manufacturers of vehicles, drones, vessels, rolling stocks and forklifts. The demand for fuel-cell systems from sectors beyond transportation such as power generation and storage systems is also expected to emerge quickly.

In May 2019, the Hyundai Motor Group announced an investment of €80 million in Rimac and is also aiming to lead the high-performance electrified vehicle market. The companies have been working closely together to develop prototypes for both an electric version of Hyundai’s N brand mid-ship sports car and a high-performance fuel cell electric vehicle with the intent to bring them to market.

In September 2019, Hyundai Hydrogen Mobility was formed - a joint venture between Hyundai Motor Company and H2 Energy. In turn, an additional partnership was forged with Hydrospider - a joint venture of H2Energy, Alpiq and Linde to promote green hydrogen ecosystem in Switzerland and other European countries. As part of this partnership, Hyundai Hydrogen Mobility plans to bring 1,600 Hyundai H2 Xcient Fuel Cell Electric Trucks, marking the entry of the automaker into Europe’s clean mobility commercial vehicle sector.

The Hyundai H2 XCIENT Fuel Cell truck features a new 190 kW hydrogen fuel cell system with two 95 kW fuel cell stacks connected in parallel. It delivers a single-fuelling travel range of more than 400 km, with a fuel storage capacity of almost 35kg of hydrogen.

Showcasing an alternative usage of our fuel cell stacks, the company previewed the Hyundai Generator, a portable charging station for electric vehicles and the newest feature of emission free electric charging at the 2019 Frankfurt Motor Show. The generator consists of two fuel cell stacks and combined hydrogen storage, giving the ability to charge two EVs simultaneously at high speed. As a comprehensive service provider of the new eTCR (Electric Touring Car Racing) championship, Hyundai will be providing the generator as a recharging system for all the cars to both showcase its technical leadership and accelerate the transition to clean e-technology.

As the Hyundai Motor Group positions itself as a global leader in clean vehicle technology, it also understands that there are considerable benefits in leveraging collective R&D capabilities across the industry. An example of this is the partnership between Hyundai Motor Group and Audi, which has seen both manufacturers share fuel cell technology developments to elevate their presence in the future fuel cell electric vehicle market.

Hyundai Motor Group also plans to strengthen its competitiveness in the fuel cell components industry, engaging in new business opportunities created by partnerships with other vehicle manufacturers. Hyundai Mobis, the leading FCEV components manufacturer of the Group, is continuously expanding its role in developing and supplying proprietary core components for Hyundai and other OEM’s fuel cell electric vehicles. Hyundai Mobis was the first company in the world to establish an integrated production system for core components of fuel cell electric vehicles and the company’s plant in Chungju, South Korea, already has the production capacity of 3,000 powertrain fuel cell complete (PFC) modules per year, and has capacity to produce tens of thousands of PFC modules down the road to meet forecast market demand. PFC modules are fuel stacks, drive motors, power electronic components and hydrogen fuel supply units.

Long ranges and short refuelling times make hydrogen an attractive future source of energy for electric mobility. This is particularly true for larger automobiles, where the weight advantages of the fuel cell vehicle inherent to its design are particularly pronounced. Key aspects for its future market success include the regenerative production of hydrogen and the establishment of a sufficient infrastructure. (MT)

Carraro Group Meets Indian Officials In Milan

- By MT Bureau

- June 06, 2025

Carraro Group’s leadership – including Ettore Francesco Sequi, Chairman of Carraro India, and Tomaso Carraro, Vice Chairman of Carraro Group and Carraro India – had a meeting with Union Minister Piyush Goyal and Indian Ambassador to Italy Vani Sarraju Rao in Milan, Italy, underscoring the deepening industrial collaboration between Italy and India, particularly in the off-highway, agriculture and construction equipment sectors.

The discussions reaffirmed Carraro Group’s long-standing commitment to India, which began in 1997. Under the motto ‘Think & Make in India’, the company has focused on developing localised solutions for the Indian market, including advanced 4WD drivetrain systems that enhance agricultural productivity and farm mechanisation. These technologies play a crucial role in supporting food security by improving efficiency for farmers, enabling higher yields and addressing global demand for sustainable food production.

Carraro India has set an ambitious growth target, aiming to increase its turnover from the current EUR 200 million to EUR 350 million by the fiscal year 2028-29. To achieve this, the company plans to expand its manufacturing facility in Pune, reinforcing its production capabilities and strengthening its supply chain within India. This expansion aligns with India’s ‘Make in India’ initiative, promoting local manufacturing and job creation while catering to both domestic and international markets.

The engagement highlights India’s growing appeal as a manufacturing and investment destination for European companies, particularly in the agricultural and construction machinery sectors. It also reflects the broader economic and technological partnership between India and Italy, fostering innovation, skill development and industrial growth.

Continental’s New Sensor Tech Measures Heat In EV Motors, Claims To Reduce Rare Earths To Protect Magnet

- By MT Bureau

- June 04, 2025

German automotive technology giant Continental has developed a new sensor technology that is said to significantly enhance the efficiency and sustainability of electric vehicle (EV) motors.

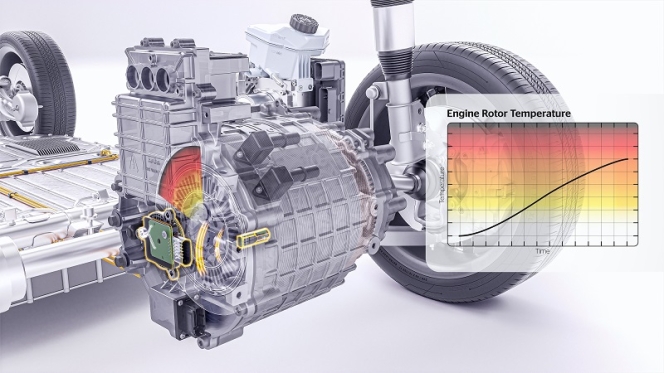

For the first time, their new e-Motor Rotor Temperature Sensor (eRTS) directly measures the temperature inside permanently excited synchronous motors on the rotor itself.

This innovative approach delivers substantially more precise measurement results than current software-based temperature simulations, drastically reducing the tolerance range from 15deg Celsius to a mere 3deg Celsius. The enhanced accuracy offers a dual benefit for vehicle manufacturers: it enables them to reduce the reliance on costly rare earth elements used to boost magnet heat resistance and simultaneously improve potential motor performance. This, in turn, paves the way for greater sustainability in EV production.

The eRTS is a key development from Continental's E-Mobility Sensors (EMS) product centre, which is dedicated to creating advanced sensor technologies for electric vehicles.

Bin Huo, Head of Passive Safety and Sensorics (PSS) segment, Continental, said, "With less resource consumption and lower costs, eRTS sensor technology is advantageous over current solutions. This innovation shows that investing resources and focusing expertise in our product centre was absolutely the right decision. We will continue to successively expand our EV sensor portfolio."

Higher Measuring Accuracy

The eRTS system comprises two distinct components: a wireless mote temperature sensor unit positioned close to the magnet within the EV motor and a wired transducer element situated outside the motor, connected to the inverter control.

Rotors operate under extreme conditions, with temperatures potentially reaching up to 150deg Celsius. Consequently, precise monitoring and control of heat development in EV motors are paramount. Presently, heat development is not measured directly but is instead calculated based on data from the stator temperature sensor, phase current measurements and environmental variables. This indirect method results in a tolerance range of up to 15deg Celsius. To safeguard magnets from demagnetisation due to excessive heat, expensive rare earth elements are typically used to cover this entire tolerance range and ensure sufficient heat resistance.

The significantly greater measuring accuracy of the eRTS, which reduces the tolerance range to just 3deg Celsius, presents car manufacturers with new design possibilities and freedom in permanent magnet synchronous EV motors.

A considerable proportion of costly rare earth materials, which would otherwise be required to account for the wider tolerance range for safety reasons, can now be saved. Furthermore, the improved accuracy offers the intriguing prospect of enhancing motor performance by pushing the operational limits closer to the actual temperature threshold.

Christoph Busch, Lead – Product Centre, Continental, said, "Our E-Mobility Sensors product centre aims to increase efficiency and sustainability in electric vehicles. The eRTS technology is a prime example of this: reducing the use of rare earths contributes to a more sustainable supply chain, especially given that the number of EVs is expected to greatly increase in the coming years and decades. In combination with other sensor technologies, such as the e-Motor Rotor Position Sensor, it can even act as a system solution to create synergies that can save car manufacturers money and effort."

Ultrasound Technology

The eRTS's two components, the mote element and the transducer element, work in tandem. The mote temperature sensor unit measures the temperature directly at the target area, as close as possible to the magnet. Crucially, the wireless mote draws its energy solely from the wired transducer, which is connected to the Electronic Control Unit (ECU) and simultaneously provides the transducer with its measuring data. The transducer is located outside the EV motor on the chassis and transmits temperature information to the inverter control via a communication interface. Both the mote and transducer communicate using Piezo ultrasound, which also facilitates the energy supply to the mote.

- Stargate

- Stargate UAE

- Cisco

- OpenAI

- Nvidia

- Softbank Group

- Oracle

- Jensen Huang

- Masayoshi Son

- Larry Ellison

- Sam Altman

- Chuck Robbins

- Peng Xiao

- G42

- Abu Dhabi

Global Tech Giants Unite To Launch Stargate UAE, Ushering A New Era Of AI Collaboration

- By MT Bureau

- June 02, 2025

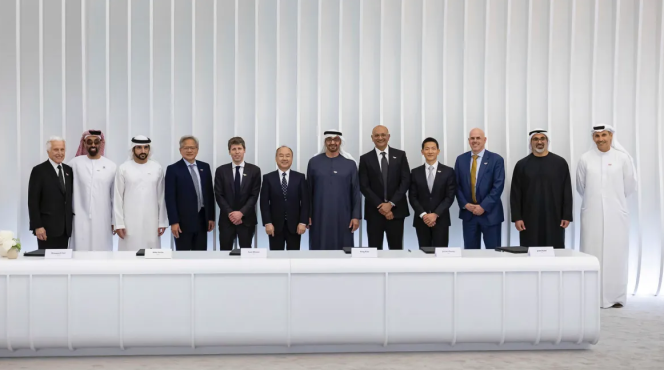

In a landmark development for artificial intelligence and global technological partnerships, G42, OpenAI, Oracle, NVIDIA, SoftBank Group and Cisco have joined forces to launch Stargate UAE, a next-generation AI infrastructure cluster set to operate in Abu Dhabi.

The announcement, made in the presence of President Sheikh Mohamed bin Zayed Al Nahyan, highlighted UAE’s commitment to driving cutting-edge innovation on the world stage.

The launch event witnessed the attendance of Sheikh Khaled bin Mohamed bin Zayed Al Nahyan, Crown Prince of Abu Dhabi, Sheikh Hamdan bin Mohammed bin Rashid Al Maktoum, Crown Prince of Dubai and Deputy Prime Minister & Minister of Defence and Sheikh Tahnoon bin Zayed Al Nahyan, Deputy Ruler of Abu Dhabi and Chairman of the Artificial Intelligence Council, alongside prominent dignitaries and senior officials.

Stargate UAE, a 1-gigawatt compute cluster, will be constructed by G42 and operated by OpenAI and Oracle. NVIDIA will provide its cutting-edge Grace Blackwell GB300 systems, while Cisco contributes AI-ready connectivity and zero-trust security frameworks. SoftBank Group will also play a crucial role in the initiative. Once operational, Stargate UAE will deliver exceptional AI infrastructure, scalable compute resources, and ultra-low latency for inferencing, enabling powerful AI applications across industries. The first 200-megawatt cluster is slated to go live in 2026.

Designed to fuel scientific discovery, industry innovation and economic growth, Stargate UAE will support sectors including healthcare, energy, finance and transportation. It forms the cornerstone of the newly announced UAE–US AI Campus, a 5-gigawatt AI hub spanning 10 square miles in Abu Dhabi – the largest deployment of its kind outside the United States. Powered by a combination of nuclear, solar and natural gas sources, the facility will prioritise sustainability and low-carbon operations. It will also feature a science park to nurture talent, advance research, and promote sustainable computing solutions.

The UAE–US AI Campus builds upon the ‘US-UAE AI Acceleration Partnership’, a framework unveiled last week by the U.S. and UAE governments to foster safe, secure and responsible AI technologies. As part of this initiative, UAE entities will expand their digital infrastructure investments in the U.S., including projects like Stargate U.S., aligned with the ‘America First Investment Policy.’

Peng Xiao, Group CEO, G42, said, “The launch of Stargate UAE is a significant step in the UAE–US AI partnership. As a founding partner, we’re proud to work alongside institutions that share our belief in responsible innovation and meaningful global progress. This initiative is about building a bridge – rooted in trust and ambition – that helps bring the benefits of AI to economies, societies, and people around the world.”

Sam Altman, Co-founder and CEO, OpenAI, said, “By establishing the world’s first Stargate outside of the US in the UAE, we’re transforming a bold vision into reality. This is the first major milestone in our OpenAI for Countries initiative – our effort to work with allies and partners to build AI infrastructure around the world. It’s a step toward ensuring some of this era’s most important breakthroughs – safer medicines, personalised learning, and modernised energy – can emerge from more places and benefit the world.”

Larry Ellison, CTO and Chairman, Oracle, said, “Stargate pairs Oracle’s AI-optimised cloud with nation-scale sovereign infrastructure. This first-in-the-world platform will enable every UAE government agency and commercial institution to connect their data to the world’s most advanced AI models. This landmark deployment sets a new standard for digital sovereignty and demonstrates how nation states can harness the power of the most important technology in the history of humankind.”

Jensen Huang, Founder and CEO, NVIDIA, said, “AI is the most transformative force of our time. With Stargate UAE, we are building the AI infrastructure to power the country’s bold vision – to empower its people, grow its economy, and shape its future.”

Masayoshi Son, Chairman and CEO, SoftBank Group, said, “When we unveiled Stargate in the US with OpenAI and Oracle, we set out to build an engine for the next information revolution. Now, the UAE becomes the first nation beyond America to embrace this sovereign AI platform, proving the global nature of this vision. SoftBank is proud to support the UAE’s leap forward. Bold investments, trusted partnerships, and national ambition can create a more connected, more joyful and more empowered world.”

Chuck Robbins, Chair and CEO, Cisco, said, “Cisco is proud to join Stargate UAE to advance groundbreaking AI innovation in the UAE and around the world. By embedding our secure AI-optimised networking fabric for this international deployment, we're building smart, secure and energy-efficient networks that will turn intelligence into impact at global scale.”

- Maruti Suzuki India

- Japan External Trade Organisation

- JETRO

- Dr Tapan Sahoo

- Takashi Suzuki

- Hisashi Takeuchi

- Accelerator

- Incubation

- Mobility Challenge

- Nurture

Maruti Suzuki and JETRO Partner to Boost India-Japan Startup Collaboration

- By MT Bureau

- May 29, 2025

Maruti Suzuki India, the country’s largest carmaker, has announced a new partnership with the Japan External Trade Organisation (JETRO) aimed at fostering innovation and creating business opportunities for startups in both India and Japan.

The collaboration, formalised through a Memorandum of Understanding (MoU), seeks to bridge the startup ecosystems of the two nations.

The MoU was formally exchanged by Dr Tapan Sahoo, Executive Officer, Digital Enterprise, Maruti Suzuki India and Takashi Suzuki, Chief Director General, JETRO India, Hisashi Takeuchi, Managing Director & CEO, Maruti Suzuki India, was also present during the signing.

As per the understanding, Maruti Suzuki India and JETRO will work together to help Indian startups gain access to Japan's innovation landscape, while Japanese startups will similarly have the opportunity to explore India's vibrant startup ecosystem.

Beyond access, the partnership will facilitate networking and participation for these startups in relevant industry events and activities, connecting them with potential partners. Indian startups selected through Maruti Suzuki's four innovation programs – Accelerator, Incubation, Mobility Challenge and Nurture – will be eligible to participate in these initiatives. Japanese startups, on the other hand, will be able to explore the Indian market through JETRO's support.

Hisashi Takeuchi, said, "Through our multi-format innovation programs, we have been engaging with startups in India to co-create technology-driven solutions relevant to the automobile manufacturing and mobility space. We see great potential in Indian startups, and with this MoU with JETRO, we will be able to provide a platform for these promising startups to explore the Japanese business landscape."

Takashi Suzuki, Chief Director General, JETRO India, said, "Maruti Suzuki stands as one of the finest examples of the successful partnership between India and Japan. With this MoU, we are creating opportunities for even more fruitful business collaborations between our two nations. This MoU aims to foster innovation, drive economic growth, and further strengthen the deep-rooted ties between India and Japan."

Comments (0)

ADD COMMENT